Understanding Bull Plug Applications in Oil and Gas Industry Operations and Maintenance

Bull Plug Oil and Gas An In-Depth Overview

The oil and gas industry has witnessed significant advancements in technology and operational efficiency in recent years. One critical component in this sector is the bull plug, a simple yet effective tool used in various applications, particularly in drilling and well operations. Understanding the role of bull plugs can provide insight into their importance in enhancing the safety and effectiveness of oil and gas extraction processes.

What is a Bull Plug?

A bull plug, commonly referred to as a plug or sealing plug, is a device designed to seal off the opening of a pipe or piping system to prevent the escape of fluids or gases. These plugs are typically made from durable materials such as rubber, metal, or plastic and can be found in various sizes to accommodate different piping dimensions. In the context of oil and gas, bull plugs are essential for maintaining system integrity during various phases, including drilling, production, and maintenance.

Applications in the Oil and Gas Industry

Bull plugs are primarily used in pressure management and fluid containment within drilling rigs and production facilities. They can be employed in well control scenarios where it is crucial to prevent the uncontrolled escape of hydrocarbons or drilling fluids. For instance, during a well shut-in or while performing maintenance, bull plugs provide a reliable barrier, ensuring safety for operators and the surrounding environment.

In addition to well control, bull plugs are also utilized during well testing and production phases. By sealing off certain sections of the pipe, operators can assess the performance of the well more effectively, measuring parameters such as pressure and flow rates, which are vital for optimizing production strategies. Furthermore, bull plugs facilitate maintenance procedures by allowing technicians to isolate components for inspection and repairs without the risk of fluid leaks.

Importance of Choosing the Right Bull Plug

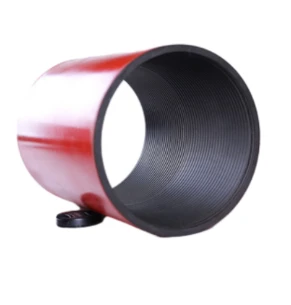

bull plug oil and gas

Selecting the appropriate bull plug is critical for ensuring effective sealing and operational safety. Factors to consider include the type of fluids being handled, the temperature and pressure conditions of the environment, and compatibility with the existing piping materials. A well-chosen bull plug not only enhances system performance but also minimizes risks associated with leaks or equipment failure.

In addition, regular inspection and maintenance of bull plugs are vital to ensure their continued efficiency. Over time, wear and tear or chemical degradation can compromise their sealing capabilities. Therefore, implementing a routine maintenance schedule can help identify potential issues before they lead to significant operational disruptions.

The Future of Bull Plugs in Oil and Gas

As the oil and gas industry continues to evolve with advancements in technology, the role of bull plugs is also set to be transformed. Innovations in materials science may lead to the development of more resilient and reliable plugging solutions, capable of withstanding extreme conditions. Additionally, the increasing emphasis on environmental sustainability may drive the demand for more eco-friendly materials in the production of bull plugs.

As companies strive to improve safety and efficiency, the importance of effective tools such as bull plugs cannot be overstated. By ensuring proper sealing and management of fluids within oil and gas systems, these devices play a crucial role in preventing accidents and optimizing production processes.

Conclusion

In summary, bull plugs are indispensable tools in the oil and gas industry. Their applications in sealing, pressure management, and maintenance are vital for ensuring operational safety and efficiency. As the industry evolves, the continuous improvement of bull plug technology will likely enhance their functionality, ultimately contributing to a safer and more productive oil and gas sector.

-

Choosing the Right Pup Joint Manufacturers for Oil and Gas OperationsNewsAug.22,2025

-

Tubing Coupling: The Small Connector with a Big ImpactNewsAug.22,2025

-

Tubing Crossover: The Essential Connector for Well IntegrityNewsAug.22,2025

-

Precision Flow Control in Well CompletionsNewsAug.22,2025

-

Casing Pup Joint for Optimal Well PerformanceNewsAug.22,2025

-

Reliable Connections with Wholesale Finished Casing CouplingNewsAug.22,2025