Stainless Steel Pipe Coupling Solutions for Optimal Connections and Durability

Understanding SS Pipe Couplings A Comprehensive Guide

In the realm of piping systems, the seamless integration of various components is crucial for ensuring both efficiency and safety. One such component that plays a vital role in this integration is the SS (stainless steel) pipe coupling. This article delves into what SS pipe couplings are, their types, applications, advantages, and considerations for choosing the right one for your needs.

What Are SS Pipe Couplings?

SS pipe couplings are fittings used to connect two pieces of pipe together, allowing for the extension of piping systems or the transition between different pipe sizes and types. Made from stainless steel, these couplings boast resistance to corrosion, high temperatures, and a range of other environmental factors that may compromise the integrity of piping systems. Their strength and durability make them a popular choice in various industries, from construction and manufacturing to oil and gas.

Types of SS Pipe Couplings

There are several types of SS pipe couplings, each designed for specific applications

1. Slip Couplings These allow for the simple connection of two pipe ends without any alterations in diameter. They are particularly useful for repairs, as they can easily slide over existing pipes.

2. Compression Couplings These utilize a series of rubber gaskets and compression fittings to create a tight seal between the two pipes. They are ideal for applications requiring a strong, leak-proof connection.

3. Threaded Couplings With external threads on one end and internal threads on the other, these couplings allow for easy assembly and disassembly. They are often employed in situations where frequent adjustments or repairs may be necessary.

4. Welded Couplings Known for their strong, permanent connection, welded couplings involve welding the coupling directly to the pipe ends. This method is favored in applications where reliability and stability are paramount.

5. Flanged Couplings These involve flanges at the ends of the coupling that allow for bolting together with matching flanges on the pipes. They are commonly used in situations where disassembly and maintenance are required.

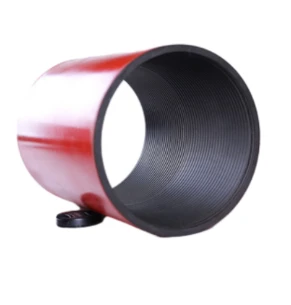

ss pipe coupling

Applications of SS Pipe Couplings

SS pipe couplings are versatile components used in numerous applications

- Water Supply Systems Ensuring connections that remain leak-free over extended periods. - Chemical Processing Its corrosion resistance makes SS couplings ideal for transporting aggressive chemicals. - Oil and Gas In demanding environments, stainless steel's durability is crucial for pipeline integrity. - Food and Beverage Hygiene is paramount in this industry; stainless steel couplings are non-reactive and easy to clean.

Advantages of SS Pipe Couplings

The use of SS pipe couplings comes with a myriad of benefits

- Corrosion Resistance Stainless steel offers superior protection against rust and corrosion compared to other materials. - Durability and Strength The robust nature of stainless steel ensures that these couplings can withstand high pressures and temperatures, making them suitable for various demanding applications. - Longevity Stainless steel's lifespan significantly exceeds that of traditional materials, leading to reduced maintenance costs and increased reliability. - Versatility Available in multiple sizes and configurations, SS couplings can be tailored to suit diverse piping needs.

Considerations When Choosing SS Pipe Couplings

When selecting SS pipe couplings, several factors must be considered

- Material Grade Different grades of stainless steel (like 304 or 316) offer varying levels of corrosion resistance and strength. Assess your application environment to choose the right grade. - Pipe Compatibility Ensure that the coupling matches the diameter and type of the pipes being connected. - Regulatory Standards In certain industries, adherence to specific standards and certifications may be necessary for compliance.

In conclusion, SS pipe couplings are indispensable components in a variety of piping systems, known for their strength, durability, and versatility. By understanding their types, applications, and benefits, one can make informed decisions when integrating these essential fittings into infrastructure projects. Whether you're involved in construction, manufacturing, or maintenance, investing in quality SS pipe couplings will surely lead to improved system performance and reliability.

-

Choosing the Right Pup Joint Manufacturers for Oil and Gas OperationsNewsAug.22,2025

-

Tubing Coupling: The Small Connector with a Big ImpactNewsAug.22,2025

-

Tubing Crossover: The Essential Connector for Well IntegrityNewsAug.22,2025

-

Precision Flow Control in Well CompletionsNewsAug.22,2025

-

Casing Pup Joint for Optimal Well PerformanceNewsAug.22,2025

-

Reliable Connections with Wholesale Finished Casing CouplingNewsAug.22,2025