- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

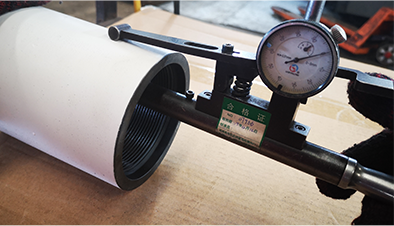

casing threads and couplings

Understanding Casing Threads and Couplings in Oil and Gas Operations

In the oil and gas industry, the successful extraction of resources requires a robust and reliable wellbore structure. Casing threads and couplings are integral components of this structure, as they not only protect the wellbore but also facilitate the connection of various tubular sections. Understanding the significance and specifications of these elements is crucial for drilling engineers and operators alike.

Casing Threads

Casing threads are specially designed helical grooves that are cut into the ends of casing pipes. These threads allow for the secure connection of casing pipes, which line the borehole and prevent the surrounding formation from collapsing. The integrity of the well is highly dependent on the quality of these threads. Various types of casing threads exist, including the American National Standard Taper (ANST) threads, API (American Petroleum Institute) threads, and premium threads, each designed for specific applications and environments.

API threads, for instance, are standardized and widely used due to their versatility and established design. They are characterized by a 1 in 16 taper and are often found in well applications where moderate pressures are expected. Premium threads, on the other hand, are designed for high-pressure and high-temperature environments, offering superior sealing capabilities and resistance to fatigue. These advanced threads often incorporate advanced metallurgy and tighter tolerances, making them suitable for challenging conditions.

Couplings

Couplings serve as connectors between individual casing lengths and are vital in maintaining the structural integrity and pressure containment of the wellbore. Typically made of moderate to high-strength steel, couplings are designed to withstand significant axial loads and internal pressures. Their quality is crucial not only for the physical connection of the casing strings but also for ensuring the overall safety and reliability of the well operation.

casing threads and couplings

Couplings can be categorized into two primary types upset and non-upset couplings. Upset couplings are thicker and designed with a more pronounced end, providing increased strength and a larger inner diameter for fluid flow. Non-upset couplings have a uniform wall thickness and are often lighter in weight, making them a preferred choice for shallower wells or less demanding environments.

The Importance of Thread Integrity

The integrity of casing threads and couplings is paramount to the success of oil and gas operations. Poorly manufactured threads or low-quality couplings can lead to catastrophic failures, including leaks and blowouts—events that not only jeopardize the safety of personnel but also result in significant financial losses and environmental damage.

Routine inspections and maintenance of these components are essential to ensure their longevity and effectiveness. Advances in technology, such as ultrasonic testing and magnetic resonance imaging, enable operators to inspect threading and coupling quality more efficiently than ever before.

Conclusion

In summary, casing threads and couplings are critical components in the oil and gas drilling process. By understanding their design, applications, and significance, industry professionals can better ensure the safety, efficiency, and success of their drilling operations. Investing in high-quality materials and technologies for casing threads and couplings is not just a matter of compliance; it is an essential strategy for operational excellence in the demanding environment of oil and gas extraction. As the industry evolves, so too will the innovations in threading and coupling technologies, paving the way for safer and more efficient resource extraction.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025