- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

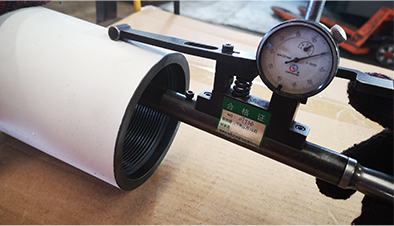

female threaded coupling

Understanding Female Threaded Couplings An Essential Component in Fluid Transfer Systems

In the diverse realm of engineering and plumbing, threaded couplings play a crucial role in ensuring the proper connection and integrity of piping systems. Among these, female threaded couplings stand out for their versatile applications and effectiveness in joining pipes of various sizes and materials. This article explores the significance, types, applications, and advantages of female threaded couplings.

What is a Female Threaded Coupling?

A female threaded coupling is a type of connector characterized by internal threads. Unlike male threaded fittings that have external threads, female couplings are designed to receive male threaded pipes or fittings. This fundamental feature allows for a secure and leak-proof connection, which is vital in systems requiring the transport of liquids or gases under pressure.

Types of Female Threaded Couplings

Female threaded couplings are available in various materials, each carefully selected based on the application requirements

1. PVC (Polyvinyl Chloride) Commonly used in plumbing applications, PVC female couplings are lightweight, resistant to corrosion, and ideal for both residential and industrial use. They are perfect for water transfer systems and are often favored for their cost-effectiveness.

2. Metal (Steel, Brass, and Stainless Steel) Female threaded couplings made of metals like brass or stainless steel are preferred for high-pressure systems. These materials resist heat and corrosion, making them suitable for oil and gas transfer, as well as in HVAC systems.

3. CPVC (Chlorinated Polyvinyl Chloride) Used in hot and cold water systems, CPVC female couplings provide additional heat resistance than standard PVC. This makes them suitable for industrial applications and residential hot water supply.

4. Polypropylene This material is ideal for chemical processing applications due to its excellent chemical resistance and ability to handle various fluid types.

Applications of Female Threaded Couplings

Female threaded couplings are employed across a broad spectrum of industries, including

female threaded coupling

- Plumbing Commonly found in residential and commercial plumbing systems, these couplings connect water supply pipes and drainage systems

. - Oil and Gas In the energy sector, female threaded couplings create reliable connections in pipes that transport crude oil, natural gas, and other hydrocarbons.- HVAC Systems They are integral in connecting ductwork and refrigerant lines in heating, ventilation, and air conditioning systems.

- Chemical Processing Their ability to withstand corrosive substances makes them ideal for chemical transport systems.

Advantages of Female Threaded Couplings

1. Ease of Installation The design of female threaded couplings allows for quick and straightforward installation. Users can easily connect or disconnect pipes without the need for special tools, enhancing overall efficiency.

2. Leak Resistance Internal threads create a tighter seal compared to many other coupling types, significantly reducing the risk of leaks. This feature is particularly important in high-pressure applications.

3. Versatility Female threaded couplings can connect pipes of different diameters, and industries can find a variety of coupling sizes to fit their needs.

4. Durability Female threaded couplings, especially those made from metal or high-quality plastics, provide longevity under various operating conditions. This durability translates to fewer replacements and reduced lifecycle costs.

5. Adaptability The ability to easily switch out male threaded pipes or fittings allows for greater adaptability in changing conditions or systems.

Conclusion

In summary, female threaded couplings are a pivotal component in various piping systems, offering reliability and efficiency in fluid transfer. Their wide range of materials and adaptability across industries make them essential for countless applications. By understanding the importance and functionality of these couplings, engineers and professionals can ensure the integrity and performance of their systems, ultimately leading to safer and more efficient operations. As technology and materials continue to evolve, the applications and benefits of female threaded couplings will expand, solidifying their role in future engineering solutions.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025