- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

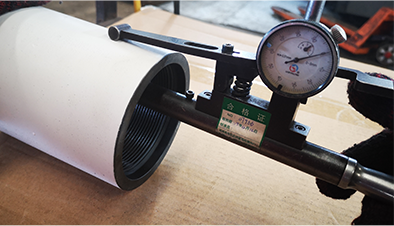

seating nipple

Understanding the Concept of Seating Nipple Importance and Applications

In various engineering and manufacturing fields, the term seating nipple refers to a critical component used in the assembly of parts, particularly in situations where maintaining pressure, spacing, or alignment is essential. While it might not be a term commonly encountered in everyday conversation, the significance of seating nipples spans across multiple industries, including automotive, aerospace, and plumbing.

What is a Seating Nipple?

A seating nipple is essentially a precision-engineered part that facilitates the connection between two components. It is designed to create a secure, leak-resistant seal, often by seating itself against a corresponding surface. The design of a seating nipple can vary significantly based on its intended application, but it typically features threads or grooves that enable it to be screwed or fitted onto other fittings or pipes. This secure connection is crucial in systems where liquids or gases are present, as it prevents leaks and maintains system integrity.

Importance of Seating Nipples

1. Leak Prevention In many applications, such as in hydraulic systems, ensuring that there are no leaks is paramount. A properly seated nipple creates a barrier that prevents the escape of fluids, thereby maintaining system pressure and functionality. Whether it’s in car engines or industrial machinery, the absence of leaks can mean the difference between smooth operation and catastrophic failure.

2. Alignment and Stability Seating nipples play a vital role in maintaining alignment between components. For instance, in plumbing applications, they ensure that pipes are correctly positioned and aligned, which is crucial for preventing stress on joints and avoiding pipe breakage.

3. Versatility Seating nipples come in various sizes, materials, and designs, making them adaptable to many applications. They can be made from metals like brass or stainless steel, or from plastics, depending on the application requirements such as resistance to corrosion or temperature changes.

4. Ease of Installation and Maintenance The installation of seating nipples is generally straightforward, allowing for quick assembly and disassembly. This feature is particularly beneficial in maintenance scenarios, where components may need to be regularly checked or replaced.

seating nipple

Applications of Seating Nipples

Seating nipples find applications across a wide array of fields

- Automotive Industry In vehicles, seating nipples are commonly used in fuel systems, cooling systems, and even the exhaust systems to ensure that connections between hoses and components are tight and leak-free.

- Aerospace In aerospace engineering, where safety and reliability are imperative, seating nipples are critical for fuel lines, hydraulic systems, and any component requiring high-pressure integrity.

- Plumbing and HVAC Systems In residential and commercial plumbing, seating nipples are essential for connecting pipes in a way that prevents leaks. Similarly, in HVAC systems, they ensure that refrigerant lines maintain the pressure needed for optimal performance.

- Industrial Equipment manufacturing machinery often relies on seating nipples to connect various hydraulic and pneumatic systems, where maintaining pressure and flow is crucial.

Conclusion

Though they may seem like small components, seating nipples play an indispensable role in various systems that require secure and reliable connections. Their ability to prevent leaks, maintain proper alignment, and allow for easy installation makes them a vital part of engineering designs.

As technology continues to evolve, the materials and designs of seating nipples will likely advance, offering even greater reliability and performance. Understanding their importance can help engineers and technicians to select the right components for their projects, ultimately leading to safer and more efficient systems. In essence, while the term seating nipple might not be widely recognized, its impact on engineering and manufacturing is significant, underscoring the idea that even the smallest parts can have a profound effect on overall performance.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025