- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

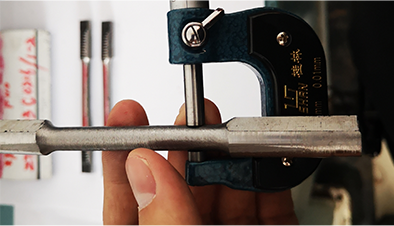

api tubing couplings

Understanding API Tubing Couplings A Comprehensive Overview

In the oil and gas industry, tubing couplings play a crucial role in ensuring the integrity and efficiency of drilling operations. Among the various standards governing these essential components, the American Petroleum Institute (API) has established a set of guidelines that enhance safety and performance. This article will delve into the specifics of API tubing couplings, their significance, types, and applications.

What are API Tubing Couplings?

API tubing couplings are specialized metal fittings designed to connect lengths of tubing in oil and gas wells. They function as a joining mechanism, allowing for the seamless transmission of fluids, gases, and pressure. The API standards specify the dimensions, materials, and performance criteria for these couplings to ensure they can withstand the harsh conditions typically found in hydrocarbon extraction.

Importance of API Standards

Adhering to API standards in tubing couplings is vital for several reasons

1. Safety Oil and gas operations involve significant risk factors, including high pressures and corrosive environments. API standards are designed to minimize the risk of failures, leaks, and accidents that could endanger lives and the environment.

2. Interchangeability API standards ensure that components sourced from different manufacturers can be used interchangeably. This facilitates maintenance, repairs, and the overall efficiency of drilling operations.

3. Quality Assurance Products that meet API specifications undergo rigorous testing and quality control, guaranteeing their reliability and durability.

Types of API Tubing Couplings

API tubing couplings can be classified into various types based on their design and purpose

api tubing couplings

1. Standard Couplings These are the most common type, typically used to connect two lengths of tubing. They must meet API specifications to ensure compatibility with API tubing.

2. Threaded Couplings These feature male and female threads that allow for secure connections. Threaded couplings are ideal in applications where high torsional resistance is required.

3. Welded Couplings These couplings are welded to the tubing, providing a permanent and robust connection. They are often employed in high-strength applications where mechanical fasteners might not provide sufficient reliability.

4. Specialty Couplings These are designed for unique applications, such as high-pressure or high-temperature environments. They may incorporate advanced materials or design features to enhance their performance.

Applications of API Tubing Couplings

API tubing couplings are used across various stages in oil and gas exploration and production. Their primary applications include

- Well Construction Couplings are fundamental during the construction of new wells, facilitating the assembly of tubing strings that transport oil and gas to the surface.

- Workover Operations In existing wells, tubing couplings allow for the removal and replacement of tubing sections during maintenance or enhancement operations.

- Production Once wells are operational, couplings play a vital role in conveying production fluids from the reservoir to processing facilities.

Conclusion

API tubing couplings are indispensable components in the oil and gas industry, serving as vital connectors that ensure the efficient flow of hydrocarbons. Their adherence to stringent API standards not only enhances operational safety and efficiency but also promotes standardization across the industry. Understanding the various types and applications of these couplings is essential for professionals in the field, as it allows for better planning, execution, and maintenance of drilling and production operations. As the industry continues to evolve, advancements in coupling technology will undoubtedly contribute to safer and more efficient energy extraction processes.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025