- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Importance of Petroleum Tubing Couplings in Oil and Gas Operations and Production

Understanding Petroleum Tubing Coupling A Critical Component in Oil and Gas Production

Petroleum tubing coupling is an essential element in the oil and gas industry, serving as a crucial link between sections of tubing in well production systems. This article explores the significance, design, types, and applications of tubing couplings, shedding light on their role in ensuring efficient and safe hydrocarbon extraction.

The Role of Tubing Couplings

In the context of petroleum production, tubing refers to the pipe that transports oil, gas, or water from the wellbore to the surface. Tubing couplings, therefore, are connectors that join two lengths of tubing together, enabling the continuation of fluid transport across different segments of a well. The integrity and reliability of these couplings are vital, as any failure could lead to leaks, reduced production efficiency, or catastrophic blowouts.

Design and Specifications

The design of petroleum tubing couplings is governed by stringent industry standards to withstand the harsh conditions encountered in subsurface environments. Factors such as pressure, temperature, and corrosiveness of the extracted fluids dictate the materials and specifications used in the manufacturing of these couplings.

Common materials for tubing couplings include carbon steel and stainless steel, known for their strength and resistance to environmental degradation. Couplings must also be designed with precision to ensure a proper seal and alignment, reducing the risk of leaks. Various dimensions and thread types are available to suit different tubing sizes and well conditions.

Types of Tubing Couplings

There are several types of petroleum tubing couplings, each designed for specific applications. The most commonly used types include

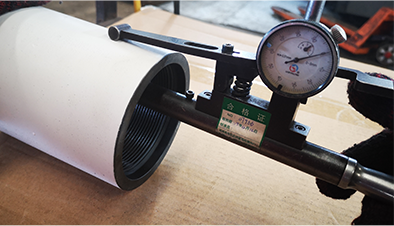

petroleum tubing coupling

1. Threaded Couplings These are the most traditional type of coupling, where the ends of the tubes are threaded together. They are easy to install and maintain but may be less robust under certain stress conditions.

2. Welded Couplings Utilizing welding techniques, these couplings are permanently joined, offering enhanced strength and durability. However, they can be more challenging to install and require skilled labor.

3. Slip Couplings Slip couplings provide flexibility in installation, allowing slight adjustments in length. They are particularly useful in situations where precise alignment is critical.

4. Box and Pin Couplings Common in modern applications, these couplings feature a box end (female) and a pin end (male). They are designed to provide a tighter seal and better resistance to torque.

Applications in the Oil and Gas Industry

Petroleum tubing couplings play a pivotal role in numerous applications within the oil and gas sector. They are used in both onshore and offshore drilling operations, ensuring fluid transport in production wells, water injection wells, and gas lift systems. Their reliability impacts the overall efficiency of hydrocarbon recovery processes.

In addition, as the industry shifts towards more complex extraction techniques such as horizontal drilling and hydraulic fracturing, the demand for innovative coupling designs that can withstand elevated stress and environmental challenges has increased. Advanced materials and engineering practices have emerged as critical contributors to improving coupling performance in these demanding applications.

Conclusion

In conclusion, petroleum tubing couplings are indispensable components of well production systems. Their design, manufacture, and application are critical for ensuring the safe and efficient transportation of hydrocarbons from the earth's depths to the surface. As the oil and gas industry continues to evolve, so too will the technologies and methods employed in designing and utilizing these couplings, reinforcing their role in the future of energy production. Understanding the intricacies of petroleum tubing couplings not only highlights their importance in the industry but also emphasizes the continuous innovation needed to meet the challenges ahead.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025