- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Seamless Tubing Connectors for Enhanced Performance and Reliability in Fluid Applications

Seamless Tubing Coupling An Overview

Seamless tubing has emerged as a crucial component in various industrial applications, particularly in the oil and gas sector, automotive industry, and construction. At the heart of seamless tubing systems lies the importance of effective couplings, specifically designed to connect lengths of tubing without the need for welding or flanging. This article delves into the significance, types, and advantages of seamless tubing couplings, shedding light on their role in ensuring the reliability and efficiency of tubing systems.

What is Seamless Tubing?

Seamless tubing is manufactured through processes that do not involve welding, resulting in a product that is stronger and free from weld-related defects. The manufacturing process typically involves a solid round steel billet, which is heated and then pierced to create a hollow tube. The tube is then elongated and reduced to the desired specifications through further processes like rolling or extrusion. The absence of seams eliminates weak points in the structure, making seamless tubing ideal for high-pressure applications and environments where durability is paramount.

Understanding Tubing Couplings

Couplings serve as connectors that link individual sections of tubing together. In seamless tubing applications, these couplings are crucial for maintaining system integrity and enabling the passage of fluids or gases. There are several types of couplings, each designed to cater to specific needs and applications. The most common types include

1. Threaded Couplings These couplings feature male and female threads that allow for easy assembly and disassembly. They are particularly popular in applications where maintenance and replacement are frequent.

2. Socket Weld Couplings Ideal for high-pressure systems, socket weld couplings provide a strong connection due to the welding process. The tubing fits into a socket, creating a robust joint once welded.

3. Flanged Couplings These couplings involve flanged ends that are bolted together, making them suitable for larger diameter pipes and high-pressure systems. They allow for easy disassembly and maintenance.

4. Compression Couplings These are used to connect two sections of tubing without welding. The connection is made through compressing the coupling onto the tubing, providing a secure fit.

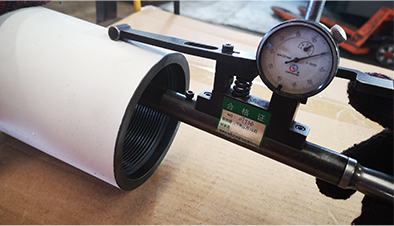

seamless tubing coupling

Advantages of Seamless Tubing Couplings

The primary advantages of seamless tubing couplings are manifold

- Durability These couplings are designed to withstand harsh conditions, including extreme temperatures and high pressure, which is essential in industries like oil and gas.

- Leak Prevention The absence of seams reduces the risk of leaks, ensuring that fluids and gases are safely contained within the tubing system.

- Strength The seamless construction allows for uniform wall thickness, resulting in enhanced strength and resistance to deformation.

- Ease of Installation Many coupling types can be installed quickly and easily, minimizing downtime during maintenance or installation processes.

- Versatility Seamless tubing couplings can be adapted for various applications, ranging from small machinery to large industrial systems.

Conclusion

Seamless tubing couplings are essential elements in the overall reliability and performance of tubing systems across numerous industries. Their ability to connect tubing sections efficiently while offering strength, durability, and leak prevention makes them a preferred choice for engineers and technicians. As industries continue to evolve and demand greater efficiency, the role of seamless tubing couplings will only become more significant, underscoring their importance in modern engineering and manufacturing practices. Emphasizing their advantages, seamless tubing couplings are indeed indispensable components in the quest for safe and efficient fluid transportation solutions.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025