- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

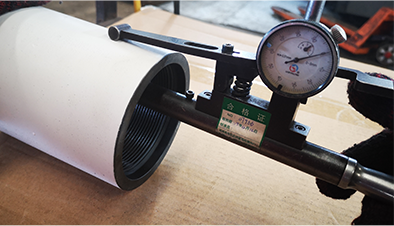

seamless tubing coupling

Understanding Seamless Tubing Couplings Applications and Benefits

Seamless tubing couplings are essential components in various industrial applications, known for their strength, reliability, and versatility. Unlike welded or threaded couplings, seamless tubing couplings are manufactured from a single piece of material, providing a continuous and uniform structure that enhances performance in demanding environments. This article will delve into the characteristics, applications, and advantages of seamless tubing couplings, highlighting their importance in modern engineering and manufacturing.

What Are Seamless Tubing Couplings?

Seamless tubing couplings are specially designed fittings used to connect sections of seamless tubing. The absence of welds in these couplings results in a structure that is less prone to failure due to stress concentration points commonly found in welded joints. This seamless design leads to stronger coupling that can withstand higher pressures and extreme temperature variations, making them ideal for critical applications in various industries.

Seamless couplings are typically made from materials such as stainless steel, alloy steel, and carbon steel, which contribute to their durability and resistance to corrosion. The manufacturing process usually involves advanced techniques such as extrusion, resulting in a product with superior mechanical properties compared to its welded counterparts. These characteristics make seamless tubing couplings suitable for use in oil and gas pipelines, chemical processing, pharmaceuticals, nuclear power stations, and more.

Applications of Seamless Tubing Couplings

1. Oil and Gas Industry Seamless tubing couplings are extensively used in the oil and gas sector for transporting fluids and gases at high pressures. The robust nature of these couplings allows them to maintain integrity even under strenuous conditions, helping to prevent leaks and ensuring safety in extraction and distribution processes.

2. Chemical Processing In chemical manufacturing, seamless couplings play a crucial role in the safe and efficient movement of corrosive substances. Their resistance to various chemicals ensures that the couplings will not degrade over time, contributing to a more reliable production process.

3. Pharmaceuticals The pharmaceutical industry requires stringent adherence to cleanliness and hygiene. Seamless tubing couplings, which can be manufactured from materials that meet food and pharmaceutical standards, are ideal for maintaining the purity of the substances being transported, thus avoiding contamination.

4. Aerospace and Defense In the aerospace and defense sectors, seamless couplings are used in hydraulic systems and fuel lines. Their ability to withstand high-pressure scenarios and extreme environmental conditions makes them a preferred choice for critical applications in aircraft and military vehicles.

seamless tubing coupling

5. Construction and Infrastructure Seamless couplings are also employed in construction and civil engineering projects. They are utilized in piping systems, structural applications, and other areas where strength and reliability are paramount.

Benefits of Using Seamless Tubing Couplings

1. Enhanced Strength and Durability The seamless design eliminates weak points typically associated with welding, resulting in couplings that are less likely to fail under high pressure or extreme temperature conditions.

2. Corrosion Resistance Many seamless couplings are made from corrosion-resistant materials, extending their lifespan and reducing the need for frequent replacements, which can save costs in the long run.

3. Versatility Seamless tubing couplings can be tailored to meet specific application needs, including size, material, and pressure ratings. This adaptability makes them suitable for a wide range of industries.

4. Improved Flow Characteristics The lack of fillets or seams in seamless couplings promotes better fluid dynamics compared to welded couplings, leading to reduced turbulence and optimized flow rates.

5. Increased Safety By minimizing the risk of leaks and failures, seamless couplings enhance the overall safety of piping systems, which is critical in high-stakes environments like oil and gas production or chemical processing.

Conclusion

Seamless tubing couplings are critical components that provide strength, reliability, and efficiency in various industrial applications. Their unique design allows for exceptional performance in harsh conditions, making them a preferred choice across multiple sectors. As industries continue to advance and evolve, the demand for seamless tubing couplings is likely to grow, reinforcing their role as indispensable elements in modern engineering solutions.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025