Feb . 20, 2025 07:42

Back to list

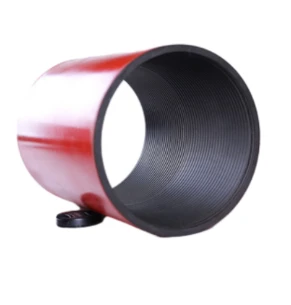

bull plug pipe layout

Bull plug pipe layout is a crucial part of the oil and gas industry's intricate infrastructure, involving the meticulous planning and implementation of capped sections within a pipeline. The key to a successful bull plug layout lies in understanding both the physical hardware requirements and the engineering expertise to ensure secure and efficient operation. This article explores the critical elements of bull plug pipe layout from an industry-professional standpoint.

While expertise in materials and engineering is crucial, trustworthiness in executing a bull plug pipe layout also relies heavily on compliance with international standards and best practices. Organizations such as the American Society for Testing and Materials (ASTM) and the American Petroleum Institute (API) provide guidelines that ensure safety and reliability. Adhering to these standards not only guarantees the structural integrity of the pipeline but also underscores a firm’s commitment to operational excellence and safety. A critical aspect of trustworthiness is the quality of installation and ongoing maintenance of bull plugs. Even the most robust design can be undermined by poor execution. Thus, deploying a skilled workforce with thorough training in both installation techniques and safety procedures is non-negotiable. Regular inspections and real-time monitoring using sensor technology can preemptively identify potential issues, facilitating timely maintenance and reducing the risk of unplanned outages or environmental incidents. The authority in designing a bull plug pipe layout also lies in the ability to innovate. The industry continuously evolves, and technologies such as smart sensors and machine learning algorithms are beginning to play significant roles. These innovations can monitor the condition of bull plugs in real-time, predict maintenance needs, and optimize system performance. Experience in deploying these systems, combined with cutting-edge technology, differentiates authoritative companies from their competitors. Case studies where advanced technologies have successfully extended the lifespan of pipeline systems or minimized environmental impact further bolster a company’s reputation. Ultimately, a comprehensive understanding of bull plug pipe layout involves integrating experience, expertise, authoritativeness, and trustworthiness into every phase of the project, from initial design through to operational management. The successful execution of these projects not only ensures the safe transportation of critical resources but also upholds environmental responsibilities and operational efficiencies that are imperative for the industry's future.

While expertise in materials and engineering is crucial, trustworthiness in executing a bull plug pipe layout also relies heavily on compliance with international standards and best practices. Organizations such as the American Society for Testing and Materials (ASTM) and the American Petroleum Institute (API) provide guidelines that ensure safety and reliability. Adhering to these standards not only guarantees the structural integrity of the pipeline but also underscores a firm’s commitment to operational excellence and safety. A critical aspect of trustworthiness is the quality of installation and ongoing maintenance of bull plugs. Even the most robust design can be undermined by poor execution. Thus, deploying a skilled workforce with thorough training in both installation techniques and safety procedures is non-negotiable. Regular inspections and real-time monitoring using sensor technology can preemptively identify potential issues, facilitating timely maintenance and reducing the risk of unplanned outages or environmental incidents. The authority in designing a bull plug pipe layout also lies in the ability to innovate. The industry continuously evolves, and technologies such as smart sensors and machine learning algorithms are beginning to play significant roles. These innovations can monitor the condition of bull plugs in real-time, predict maintenance needs, and optimize system performance. Experience in deploying these systems, combined with cutting-edge technology, differentiates authoritative companies from their competitors. Case studies where advanced technologies have successfully extended the lifespan of pipeline systems or minimized environmental impact further bolster a company’s reputation. Ultimately, a comprehensive understanding of bull plug pipe layout involves integrating experience, expertise, authoritativeness, and trustworthiness into every phase of the project, from initial design through to operational management. The successful execution of these projects not only ensures the safe transportation of critical resources but also upholds environmental responsibilities and operational efficiencies that are imperative for the industry's future.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products