- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

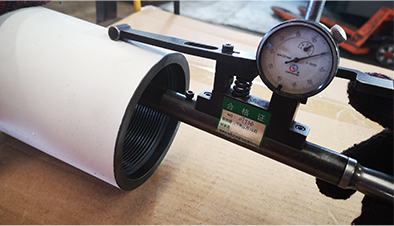

api 5ct casing coupling

Understanding API 5CT Casing Couplings

In the realm of oil and gas drilling, the importance of casing and its components cannot be overstated. The API 5CT standard defines the specifications for steel casing pipes and couplings, which are crucial for maintaining the integrity and safety of drilling operations. This article aims to provide an overview of the API 5CT casing coupling, its types, applications, and significance in the industry.

What is API 5CT?

API 5CT is a standard established by the American Petroleum Institute (API) which governs the specifications for steel casing and tubing used in the drilling of oil and gas wells. The standard outlines the design, material properties, testing procedures, and manufacturing practices necessary to ensure quality and reliability in the various components used in the extraction of hydrocarbons. The casing serves multiple purposes, including providing structural support to the wellbore, isolating different underground formations, and preventing the migration of fluids.

Casing Couplings Explained

Casing couplings are connectors that join two lengths of casing pipes together, allowing for seamless continuation of the casing string. These couplings must meet strict standards to ensure they can withstand the high pressures and corrosive environments found in oil and gas wells. API 5CT specifies various grades of casing steel, each suitable for different conditions and pressures encountered during drilling operations.

Types of API 5CT Casing Couplings

api 5ct casing coupling

The API 5CT standard classifies casing couplings primarily based on their material grades, which include

1. H-40 This grade is often used in shallow wells because of its high strength and low cost. 2. J-55 Suitable for moderate pressure use, J-55 offers good yield strength, making it a popular choice in a range of applications. 3. K-55 This grade provides enhanced strength and is commonly employed in deeper well applications. 4. N-80 Known for its resistance to corrosion and high-temperature conditions, N-80 is utilized in challenging environments. 5. L-80 This grade has added alloying elements to ensure improved toughness and strength, ideal for use in sour gas wells.

Each coupling grade has its specifications regarding mechanical properties, chemical composition, and heat treatment, ensuring they fit a variety of operating conditions.

Applications and Importance

Casing couplings are essential for maintaining the structural integrity of the well. They help prevent collapse of the wellbore and protect against the influx of unwanted fluids, which can result in dangerous blowouts. Moreover, proper coupling ensures the casing is properly sealed, thus preventing cross-contamination between different fluid formations.

In conclusion, API 5CT casing couplings are vital components in oil and gas drilling operations. They not only connect casing pipes but also play a fundamental role in the structural integrity and safety of drilling activities. Understanding the specifications and applications of these couplings is crucial for anyone involved in the drilling industry, from engineers to procurement specialists, ensuring that the operations meet safety and efficiency standards.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025