- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Comprehensive Overview of Pup Joint Specifications for Efficient Oil and Gas Operations

Understanding PUP Joint Specifications

PUP joints, or Pipe Union Pipe joints, are essential components in various piping systems, primarily utilized in the oil and gas industry, water treatment facilities, and other sectors that employ fluid transportation. These joints play a crucial role in ensuring the integrity and efficiency of piping systems, facilitating easy assembly and disassembly while maintaining reliable seals under pressure. In this article, we will explore the specifications of PUP joints, their applications, and the importance of adhering to industry standards.

What Are PUP Joints?

PUP joints are specially designed pipe sections that serve as connectors between two pipe ends in a system. They allow for quick replacement or maintenance, minimizing downtime during operation. The design of PUP joints typically incorporates a series of threads, o-rings, or flanges to ensure a leak-proof connection. Their versatility makes them suitable for various pressures and temperatures, accommodating the diverse needs of different industrial applications.

Specifications of PUP Joints

1. Material Composition PUP joints are made from various materials, including carbon steel, stainless steel, and alloys that can withstand corrosive environments. The choice of material is critical, as it affects the joint's strength, durability, and resistance to environmental factors.

2. Size and Dimensions PUP joints come in various sizes to fit a range of piping systems. Standard sizes often follow industry norms, with diameters typically ranging from 1 inch to 24 inches or more. Accurate sizing is vital to ensure compatibility with existing systems.

3. Pressure Ratings PUP joints are rated for specific pressure levels, usually depicted in terms of PSI (pounds per square inch). These ratings inform users of the maximum pressure the joint can withstand without failing. It’s imperative to choose a joint that meets or exceeds the pressure requirements of the system.

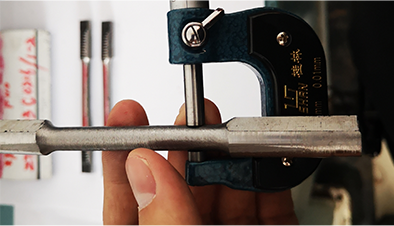

pup joint specifications

4. Temperature Ratings The operational temperature range is another critical specification. Different materials exhibit varying degrees of thermal stability, which can affect the performance of the PUP joint under high or low-temperature conditions.

5. Sealing Mechanisms Effective sealing is essential to prevent leaks. PUP joints may incorporate various sealing technologies, including rubber o-rings, PTFE seals, or metallic gaskets, designed to provide a tight fit and withstand pressure variations.

6. Standards and Certifications Compliance with industry standards such as ASME (American Society of Mechanical Engineers) and API (American Petroleum Institute) is paramount. These certifications ensure that PUP joints meet safety and performance criteria essential for operation in hazardous environments.

Applications

PUP joints are widely employed in numerous applications across industries

- Oil and Gas In drilling operations and extraction processes, PUP joints ensure secure connections amid high pressure and challenging environmental conditions. - Water and Wastewater Management These joints are integral in pipelines for water supply, treatment, and distribution, helping to maintain the quality and safety of water systems. - Chemical Processing In chemical plants, PUP joints are utilized to transport corrosive or hazardous materials, where reliable sealing is crucial.

Conclusion

In summary, PUP joint specifications are vital for ensuring the safety, reliability, and efficiency of piping systems across various industries. Understanding the material composition, size, pressure and temperature ratings, sealing mechanisms, and compliance with industry standards is essential for selecting the right PUP joint for a particular application. As technology advances, innovations in PUP joint design will likely continue to enhance their performance and durability, addressing the ever-evolving needs of industrial operations. Ultimately, investing in high-quality PUP joints can significantly contribute to the overall success and reliability of fluid transportation systems.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025