- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

juuni . 26, 2024 16:27

Back to list

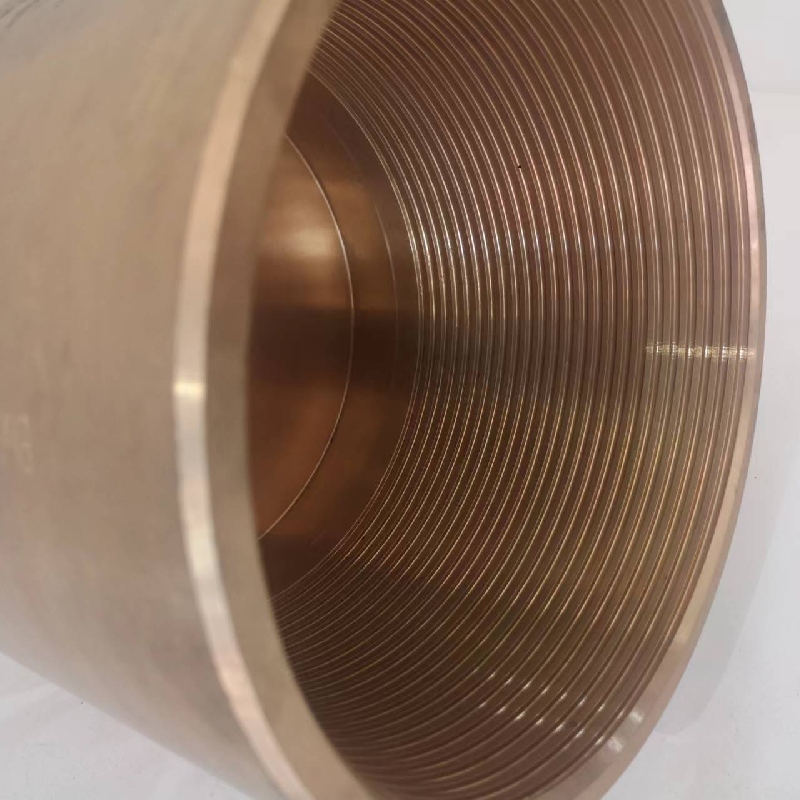

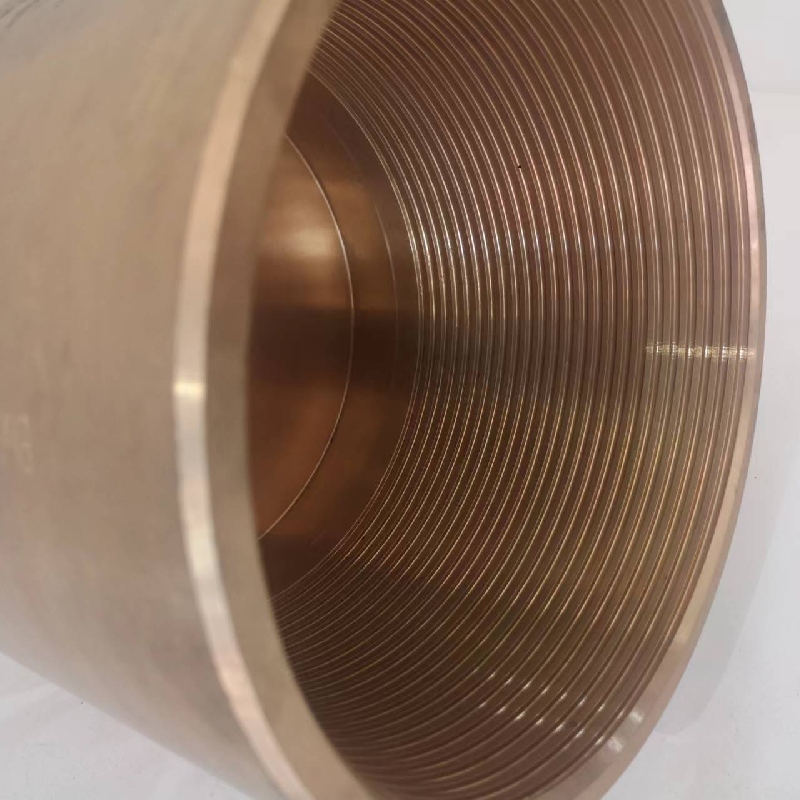

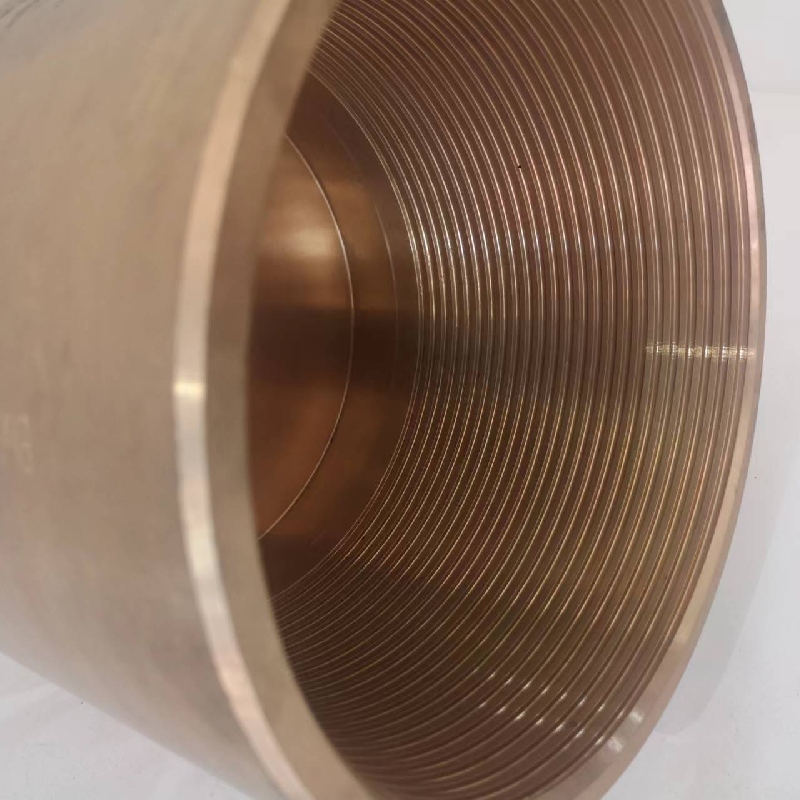

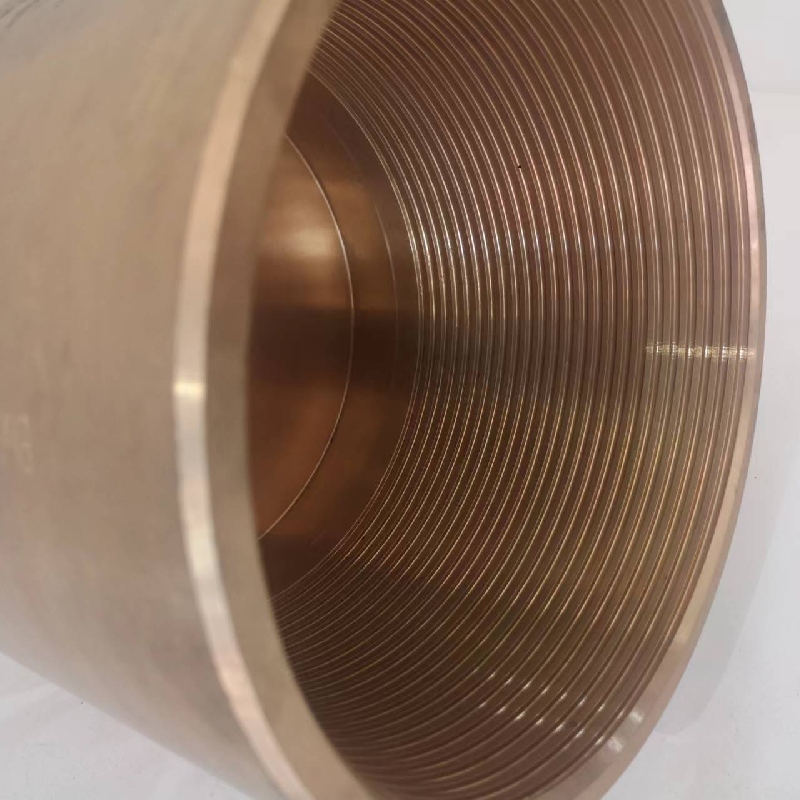

Optimal Design and Analysis of Oil Well Casing Connections

The Vital Role of Well Casing Coupling in Oil and Gas Exploration

Well casing coupling is an integral component in the complex and intricate process of oil and gas exploration. It serves as the connecting element between sections of casing pipes, ensuring the structural integrity and stability of the wellbore during drilling operations. This critical piece of equipment plays a pivotal role in safeguarding both personnel and the environment, making it an indispensable aspect of the industry.

Casing, essentially, is a long steel tube that is lowered into a borehole to provide support to the well walls, preventing cave-ins and controlling fluid migration. Casing couplings, on the other hand, are the mechanical connectors that join these lengths of casing together, forming a continuous conduit from the surface to the target depth. They are designed to withstand immense pressures, temperatures, and the dynamic forces exerted during drilling and production phases.

The primary function of well casing coupling is to maintain a secure seal between the casing joints. This seal is essential to prevent the ingress of formation fluids into the wellbore and the egress of drilling fluids into the surrounding formation. The coupling's design typically includes threads, which engage with corresponding threads on the casing ends, creating a tight connection. The thread design is crucial, as it affects the strength, sealing capability, and ease of make-up and break-out.

Moreover, well casing couplings also contribute to the overall strength of the casing string

Moreover, well casing couplings also contribute to the overall strength of the casing string Moreover, well casing couplings also contribute to the overall strength of the casing string

Moreover, well casing couplings also contribute to the overall strength of the casing string

Moreover, well casing couplings also contribute to the overall strength of the casing string

Moreover, well casing couplings also contribute to the overall strength of the casing string well casing coupling. They must be robust enough to resist the high tensile and compressive loads encountered during drilling, completion, and production. These loads can arise from various sources such as the weight of the casing itself, the pressure of the drilling fluid, and the forces generated by the rotating drill bit.

In addition to their functional importance, well casing couplings also have a significant impact on operational efficiency. A smooth and efficient coupling process can save valuable time and reduce the risk of accidents or equipment damage. The choice of material for the coupling, usually high-strength steel, is critical to ensure durability and resistance to corrosion, particularly in harsh environments.

In conclusion, well casing coupling is not just a technical detail but a cornerstone of safe and effective oil and gas drilling. Its role extends beyond mere physical connection; it ensures the stability of the well, protects against environmental hazards, and contributes to overall operational efficiency. As technology advances, so does the sophistication of these couplings, further enhancing their performance and reliability in the challenging world of oil and gas exploration.

well casing coupling. They must be robust enough to resist the high tensile and compressive loads encountered during drilling, completion, and production. These loads can arise from various sources such as the weight of the casing itself, the pressure of the drilling fluid, and the forces generated by the rotating drill bit.

In addition to their functional importance, well casing couplings also have a significant impact on operational efficiency. A smooth and efficient coupling process can save valuable time and reduce the risk of accidents or equipment damage. The choice of material for the coupling, usually high-strength steel, is critical to ensure durability and resistance to corrosion, particularly in harsh environments.

In conclusion, well casing coupling is not just a technical detail but a cornerstone of safe and effective oil and gas drilling. Its role extends beyond mere physical connection; it ensures the stability of the well, protects against environmental hazards, and contributes to overall operational efficiency. As technology advances, so does the sophistication of these couplings, further enhancing their performance and reliability in the challenging world of oil and gas exploration.

Moreover, well casing couplings also contribute to the overall strength of the casing string

Moreover, well casing couplings also contribute to the overall strength of the casing string

Moreover, well casing couplings also contribute to the overall strength of the casing string

Moreover, well casing couplings also contribute to the overall strength of the casing string well casing coupling. They must be robust enough to resist the high tensile and compressive loads encountered during drilling, completion, and production. These loads can arise from various sources such as the weight of the casing itself, the pressure of the drilling fluid, and the forces generated by the rotating drill bit.

In addition to their functional importance, well casing couplings also have a significant impact on operational efficiency. A smooth and efficient coupling process can save valuable time and reduce the risk of accidents or equipment damage. The choice of material for the coupling, usually high-strength steel, is critical to ensure durability and resistance to corrosion, particularly in harsh environments.

In conclusion, well casing coupling is not just a technical detail but a cornerstone of safe and effective oil and gas drilling. Its role extends beyond mere physical connection; it ensures the stability of the well, protects against environmental hazards, and contributes to overall operational efficiency. As technology advances, so does the sophistication of these couplings, further enhancing their performance and reliability in the challenging world of oil and gas exploration.

well casing coupling. They must be robust enough to resist the high tensile and compressive loads encountered during drilling, completion, and production. These loads can arise from various sources such as the weight of the casing itself, the pressure of the drilling fluid, and the forces generated by the rotating drill bit.

In addition to their functional importance, well casing couplings also have a significant impact on operational efficiency. A smooth and efficient coupling process can save valuable time and reduce the risk of accidents or equipment damage. The choice of material for the coupling, usually high-strength steel, is critical to ensure durability and resistance to corrosion, particularly in harsh environments.

In conclusion, well casing coupling is not just a technical detail but a cornerstone of safe and effective oil and gas drilling. Its role extends beyond mere physical connection; it ensures the stability of the well, protects against environmental hazards, and contributes to overall operational efficiency. As technology advances, so does the sophistication of these couplings, further enhancing their performance and reliability in the challenging world of oil and gas exploration. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products