- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Bull Plug Pipe Arrangement Design for Optimal Fluid Flow Management

The Bull Plug Pipe Layout A Comprehensive Overview

In the world of fluid transportation and infrastructure, the design and implementation of piping systems hold paramount importance. Among the various configurations that engineers utilize, the bull plug pipe layout has emerged as a significant option for various industrial applications. This article delves into the characteristics, advantages, and applications of bull plug pipe layouts, shedding light on why they are favored in numerous sectors.

What is a Bull Plug Pipe Layout?

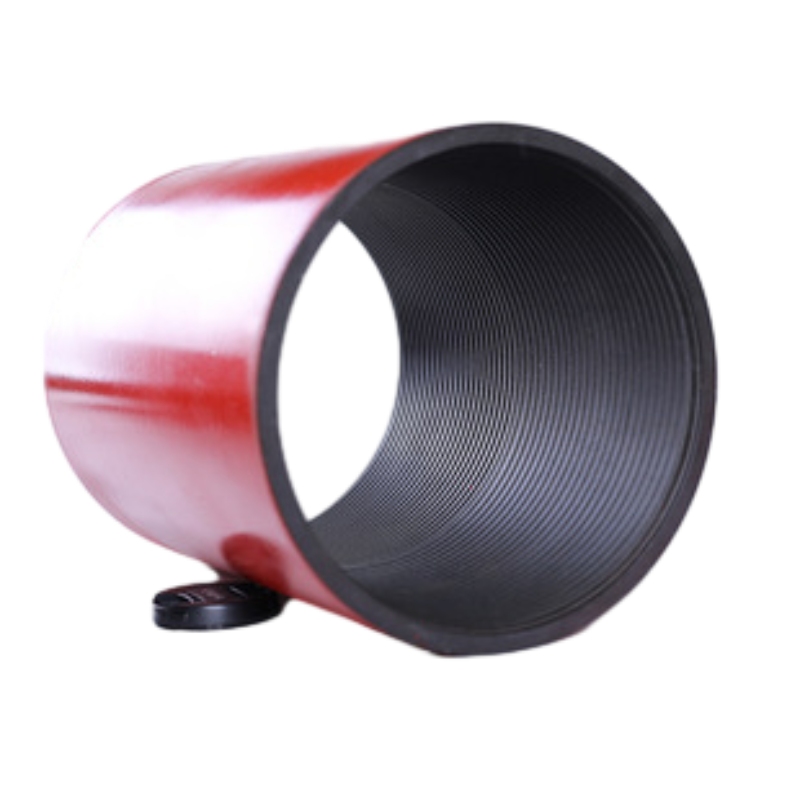

A bull plug pipe layout is characterized by the use of bull plugs—fittings that serve as closures for pipes, primarily within a piping system. Essentially, a bull plug has a conical tip that allows for a tight seal, preventing leaks and ensuring the efficient flow of liquids or gases. This design is particularly beneficial in systems where pressure regulation and leak prevention are critical.

The layout of a pipe system incorporating bull plugs must be meticulously planned. Effective bull plug pipe arrangements consider factors such as the dimensions of the pipes, flow direction, and intended uses. Engineers often utilize CAD software to simulate fluid dynamics and optimize the arrangement before physical implementation, thereby increasing operational efficiency.

Advantages of Bull Plug Pipe Layouts

1. Leak Prevention One of the most significant advantages of using bull plugs in piping systems is their effectiveness in preventing leaks. The design ensures a secure fit, which is essential for systems carrying hazardous or high-pressure fluids.

2. Ease of Installation Bull plugs are typically straightforward to install, which simplifies the assembly process. This ease can lead to reduced labor costs and shorter project timelines.

3. Pressure Management For applications that operate under high-pressure conditions, bull plugs provide a reliable solution. They help maintain the integrity of the system, minimizing the risks associated with pressure fluctuations.

bull plug pipe layout

4. Versatility Bull plug pipe layouts can be adapted for various applications, from water treatment plants to oil refineries. Their versatility makes them suitable for industries ranging from construction to manufacturing.

5. Durability The materials used for bull plugs—including metal, plastic, or composite—are chosen for their resilience. This durability ensures that they withstand environmental factors and the corrosive nature of some transported materials.

Applications of Bull Plug Pipe Layouts

1. Oil and Gas Industry The oil and gas sector often employs bull plug pipe layouts due to the high pressures and hazards associated with transporting hydrocarbons. Bull plugs ensure the safety and effectiveness of the entire system.

2. Water Supply Systems Municipal water supply networks utilize these layouts to maintain water quality and prevent contamination. Bull plugs help in isolating sections of the pipeline for maintenance without disrupting the overall supply.

3. Chemical Processing Plants In chemical manufacturing, maintaining the integrity of piping systems is crucial. Bull plugs provide a reliable solution for managing dangerous chemicals and preventing leaks that could lead to catastrophic situations.

4. Construction In construction projects, bull plug pipe layouts are essential during the early stages for temporary closures and to manage water flow. Their ease of use allows for flexibility as project needs change.

Conclusion

In summary, the bull plug pipe layout is an essential strategy in the design and implementation of piping systems across diverse industries. Its advantages, including leak prevention, ease of installation, pressure management, versatility, and durability, make it a preferred choice for engineers and technicians alike. As industries continue to innovate and grow, the demand for efficient and reliable piping solutions like bull plug layouts will undeniably persist, ensuring that fluid transport remains seamless and safe. Understanding and leveraging the potential of such designs is crucial for achieving long-term success in any fluid management system.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025