- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Key Distinctions Between Casing and Tubing in Oil and Gas Operations

Understanding the Differences Between Casing and Tubing in Oil and Gas Operations

In the oil and gas industry, the terms casing and tubing are often used interchangeably by those unfamiliar with their distinct roles in drilling and production operations. However, these two components serve very different purposes and are crucial for the success and safety of oil and gas extraction. This article delves into the characteristics, functions, and differences between casing and tubing.

What is Casing?

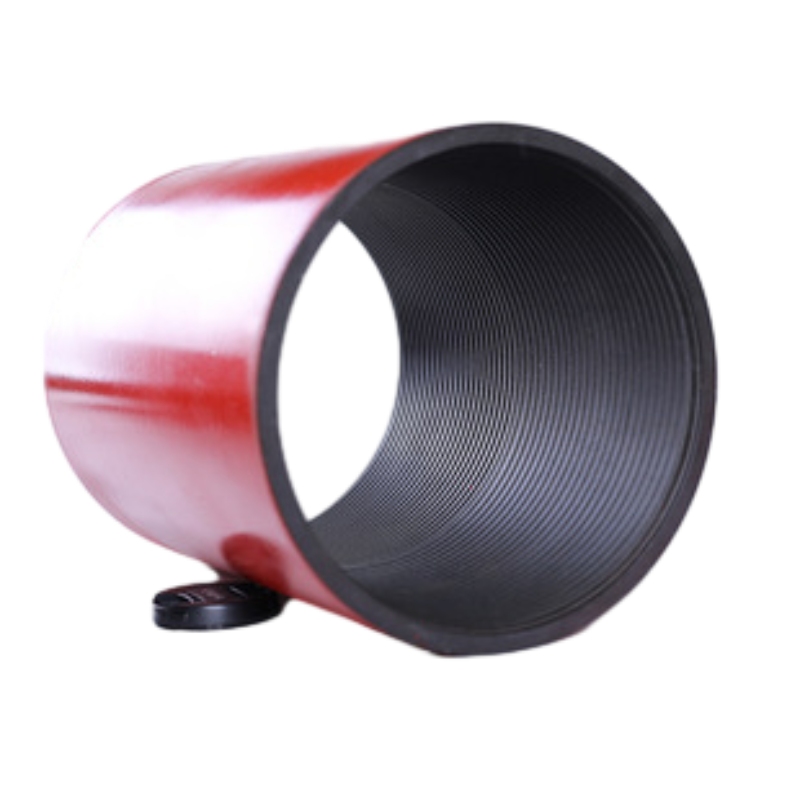

Casing is a series of steel pipes that are inserted into a drilled wellbore to provide structural support to the well's walls. The primary function of casing is to prevent the well from collapsing and to isolate different underground formations. This is vital for maintaining an open, safe passage for the extraction of hydrocarbons and for protecting groundwater resources from contamination.

Casing is installed in sections and is typically cemented in place. The cement creates a seal between the casing and the borehole walls, preventing fluid migration between different formations. This is especially important in multi-zone wells where different reservoirs are present at various depths. The use of casing significantly enhances the safety and efficiency of the drilling process by preventing blowouts and controlling subsurface pressures.

There are various types of casing, including surface casing, intermediate casing, and production casing, each designed for specific depths and operational requirements. Surface casing, for instance, is the first layer placed in the well and extends from the surface down to a certain depth to protect freshwater zones. Production casing follows, running through the producing zones to facilitate the extraction of hydrocarbons.

What is Tubing?

Tubing, on the other hand, is the pipe that is installed inside the casing to transport hydrocarbons from the reservoir to the surface. Once the well has been drilled and cased, tubing is inserted through the production casing. This thin-walled pipe is essential for carrying oil, gas, and other fluids extracted from the well to the surface processing facilities.

Tubing is designed to withstand high pressure and is often made from materials that can resist corrosion caused by the production fluids. Unlike casing, tubing is not meant for structural support; instead, it focuses on maximizing the flow of fluids. Depending on the production conditions, the tubing can also be equipped with valves and pumps to enhance the efficiency of fluid extraction.

what are the differences between casing and tubing?

One important aspect of tubing is its ability to be retrieved and replaced without having to remove the entire casing

. This makes maintenance and repairs easier, allowing operators to address issues such as scaling or corrosion without compromising the integrity of the well structure.Key Differences Between Casing and Tubing

1. Purpose The primary purpose of casing is to provide structural integrity to the well and prevent the collapse of the wellbore, while tubing is intended for the transport of hydrocarbons from the reservoir to the surface.

2. Location Casing is installed in the wellbore first and remains there permanently, cemented in place. Tubing is installed after casing and can be removed and replaced as needed.

3. Design Casing is typically thicker and designed for strength and stability, while tubing is thinner-walled and specifically designed for the efficient flow of produced fluids.

4. Installation Process Casing is cemented in place after installation, creating a secure seal, whereas tubing is run inside the casing and can be fitted with various components to optimize fluid transport.

5. Maintenance Casing requires minimal maintenance after installation, as it is a permanent structure. In contrast, tubing may require regular inspection and replacement due to wear and tear from the continuous flow of fluids.

Conclusion

In summary, casing and tubing are both vital components of oil and gas well construction, but they serve very different functions. Understanding these differences is essential for ensuring the safety, efficiency, and effectiveness of oil and gas operations. Proper management and maintenance of both casing and tubing systems are crucial for successful resource extraction and environmental protection.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025