- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

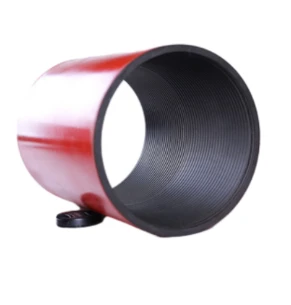

Stainless Steel Couplings for Reliable Industrial and Plumbing Applications

Understanding Stainless Steel Couplings Features, Benefits, and Applications

In various industrial and engineering applications, ensuring secure and reliable connections between different components is vital. One prevalent solution to achieving this are stainless steel couplings. These robust fittings facilitate the attachment of shafts, pipes, or hoses, providing a seamless conduit for the transfer of fluids, gases, or mechanical power. This article delves into the features, benefits, and wide-ranging applications of stainless steel couplings.

What are Stainless Steel Couplings?

Stainless steel couplings are mechanical devices used to connect two shafts together. They are designed to accommodate any misalignment in the shafts while transmitting power from one to another. These couplings are typically made from stainless steel alloys, which are known for their excellent resistance to corrosion, high tensile strength, and prolonged durability. Commonly, these couplings come in various designs, including rigid, flexible, and universal types, catering to different requirements and installation scenarios.

Key Features of Stainless Steel Couplings

1. Corrosion Resistance One of the standout features of stainless steel is its innate ability to withstand corrosion, making these couplings ideal for applications in harsh environments such as chemical processing and food industries.

2. Durability Stainless steel possesses high tensile strength, allowing couplings to operate effectively under high loads and stress without deforming or breaking.

3. Versatility These couplings can accommodate various shaft diameters and configurations, which allows for adaptability in numerous applications. They are compatible with different industries, including automotive, aerospace, and manufacturing.

4. Temperature Resistance Stainless steel couplings can maintain structural integrity and performance at both high and low temperatures, making them suitable for extreme operating conditions.

5. Ease of Installation and Maintenance These couplings are generally straightforward to install and operate. Minimal maintenance is required due to their robust construction, which can significantly reduce downtime in industrial settings.

Benefits of Using Stainless Steel Couplings

The benefits of incorporating stainless steel couplings into systems are multi-faceted

1. Enhanced Reliability The robust design and material properties bolster the overall reliability of the systems they are integrated into, reducing the likelihood of failure and maintenance issues.

stainless steel coupling

3. Cost-Effectiveness While the initial investment in stainless steel couplings may be higher than other materials, the durability and longevity lead to reduced replacement and repair costs.

4. Improved Performance The efficient power transfer capabilities of stainless steel couplings enhance the performance of machinery and equipment, leading to increased productivity.

Applications of Stainless Steel Couplings

Stainless steel couplings find extensive use across several industries

1. Chemical Processing Given their resistance to corrosive substances, stainless steel couplings are critically used in piping systems that transport chemicals.

2. Food and Beverage Industry These couplings comply with stringent hygiene standards, making them suitable for food processing and packaging machinery.

3. Marine Engineering Stainless steel’s commendable resistance to saltwater corrosion makes these couplings a preferred choice in marine applications.

4. Automotive and Aerospace The lightweight yet sturdy nature of stainless steel couplings enhances performance and efficiency in vehicles and aircraft.

5. Manufacturing These couplings are integral in various manufacturing machinery, where reliable connections are essential for efficient operations.

Conclusion

In summary, stainless steel couplings are indispensable components across numerous industrial applications due to their durability, corrosion resistance, and versatility. By understanding their features and benefits, engineers and procurement specialists can make informed decisions to enhance system performance and reliability. With the capacity to withstand demanding conditions, stainless steel couplings truly exemplify the marriage of functionality and resilience in engineering solutions.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025