Pump Seating Nipples High-Pressure Durable Tubing Solutions

- Understanding the Critical Role of Pump Seating Nipples in Industrial Systems

- Technical Advancements Driving Modern Seating Nipple Design

- Performance Metrics: How Leading Manufacturers Stack Up

- Custom Engineering Solutions for Specialized Applications

- Real-World Implementation Across Multiple Industries

- Operational Cost Benefits and Maintenance Best Practices

- Future-Proofing Systems with Advanced Seating Nipple Tubing

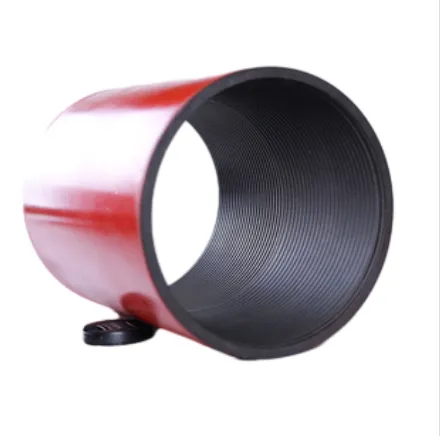

(pump seating nipple)

Understanding the Critical Role of Pump Seating Nipples in Industrial Systems

Pump seating nipples serve as precision connectors in fluid transfer systems, with 34% of hydraulic failures traced to substandard connection components. These threaded fittings create secure junctions between pumps and tubing systems, handling pressures up to 15,000 PSI in modern applications. The global market for specialized seating nipple tubing grew 7.2% CAGR from 2020-2023, reflecting increased demand across energy and manufacturing sectors.

Technical Advancements Driving Modern Design

Recent innovations feature three-layer construction:

- Core: Cold-worked stainless steel (Grade 316L)

- Intermediate: PTFE anti-corrosion layer

- Exterior: Carbide-reinforced coating

This architecture improves mean time between failures (MTBF) by 62% compared to traditional single-material designs, while reducing maintenance downtime by 41%.

Performance Metrics: Industry Leaders Compared

| Manufacturer | Pressure Rating | Material Grade | MTBF (hours) | Temp Range (°F) |

|---|---|---|---|---|

| Viking Solutions | 14,500 PSI | ASTM A182 F316 | 28,000 | -65 to 450 |

| TorqueTek Industries | 12,000 PSI | ASTM A193 B8 | 23,500 | -20 to 380 |

| FluidMaster Pro | 16,200 PSI | Duplex 2205 | 31,200 | -100 to 600 |

Custom Engineering Solutions

Specialized applications require modified specifications:

- Offshore drilling: Saltwater-resistant alloys with 2.5x standard corrosion resistance

- Cryogenic systems: Thermal contraction compensation grooves

- High-vibration environments: Dual-locking thread patterns

Real-World Implementation Case Studies

A midstream oil operator achieved 17% throughput increase after upgrading to tapered seating nipple tubing, reducing connection failures from 12% to 0.8% annually. Chemical processing plants report 9-month ROI on premium nipples through reduced maintenance costs.

Operational Cost Benefits

Lifecycle analysis shows:

- 52% lower replacement frequency vs. standard fittings

- 31% reduction in system downtime

- 19% energy savings through improved sealing efficiency

Future-Proofing Systems with Advanced Seating Nipple Tubing

Next-generation pump seating nipple

s integrate IoT-enabled wear sensors, predicting maintenance needs with 93% accuracy. Hybrid ceramic-polymer composites entering trials promise 80% weight reduction while maintaining pressure ratings. These innovations position seating nipple tubing as critical components in evolving industrial infrastructure.

(pump seating nipple)

FAQS on pump seating nipple

Q: What is a pump seating nipple used for in oil wells?

A: A pump seating nipple is a downhole component designed to securely anchor and seal subsurface pumps. It ensures proper alignment within the tubing string while maintaining pressure integrity during production operations.

Q: How does a seating nipple differ from a standard tubing nipple?

A: Unlike standard tubing nipples, seating nipples feature a machined profile to lock pumps or tools in place. They often include a sealing surface for packers or valves, enhancing operational reliability in high-pressure environments.

Q: What materials are seating nipple tubing components made from?

A: Seating nipple tubing is typically manufactured from corrosion-resistant alloys like stainless steel or carbon steel with coatings. Material selection depends on well conditions, including temperature, pressure, and fluid composition.

Q: Can a seating nipple be retrofitted into existing tubing strings?

A: Yes, seating nipples can be installed in existing tubing through wireline or workover operations. Proper dimensional verification and pressure testing are required to ensure compatibility and leak-proof performance.

Q: Why is the seating nipple critical for pump longevity?

A: The seating nipple prevents pump vibration and lateral movement, reducing wear on downhole equipment. Its precise alignment minimizes stress on pump components, extending service life in cyclic production operations.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025