- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

API 5CT Tubing Coupling Specifications and Applications in Oil and Gas Industry

Understanding API 5CT Tubing Couplings A Key Component in Oil and Gas Industry

In the oil and gas industry, the transportation of fluids from underground formations to the surface is crucial for extracting valuable resources. One essential component that plays a significant role in this process is the tubing coupling. This article delves into API 5CT tubing couplings, their specifications, types, applications, and importance in ensuring the integrity of well systems.

What is API 5CT?

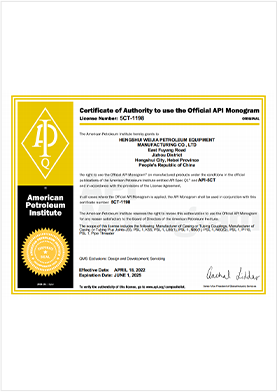

API 5CT is a standard established by the American Petroleum Institute (API), which outlines the specifications for casing and tubing used in the extraction of oil and gas. It provides guidelines for materials, dimensions, manufacturing processes, and testing methods for tubular goods. API 5CT ensures that these materials can withstand the extreme conditions (e.g., high pressure and temperature) present in subsurface environments.

What are Tubing Couplings?

Tubing couplings are mechanical devices that join lengths of tubing together, enabling the continued flow of fluids from the wellbore to the surface. They are designed to connect two ends of tubing and maintain the integrity of the entire system. Couplings not only provide mechanical strength but also prevent leaks, which can be hazardous and costly.

Types of API 5CT Tubing Couplings

API 5CT tubing couplings are classified based on their design and application. The common types include

1. Regular Couplings (R) These are standard couplings used primarily for connecting tubing and casing. They have a simple design and are widely utilized in various applications.

2. Long Couplings (L) These are used in scenarios where additional thread engagement is needed. Long couplings are often preferred in severe service conditions.

api 5ct tubing coupling

3. Special Couplings These include couplings designed for specific applications or conditions, such as those that need to withstand corrosive environments or high-temperature settings.

Specifications of API 5CT Tubing Couplings

API 5CT tubing couplings come with specific material and mechanical property requirements. Typically made from carbon steel, these couplings must satisfy standards regarding yield strength, tensile strength, and elongation. The common grades of API 5CT tubing couplings include K55, N80, L80, and P110, each with varying mechanical properties suited for different applications.

The dimensions of couplings (such as length and outer diameter) are also standardized under API 5CT to ensure compatibility with various tubing sizes and connections. Properly adhering to these specifications is critical for the performance and safety of oil and gas operations.

Importance of Tubing Couplings in Well Integrity

The integrity of a well is paramount for the safety and efficiency of oil and gas extraction. API 5CT tubing couplings contribute to this integrity by ensuring proper sealing and resistance to external pressures. A failure in the coupling can lead to substantial issues, including leaks, blowouts, or equipment damage.

Moreover, the choice of the right coupling type and grade is essential based on the specific well conditions. Factors such as temperature, pressure, and the chemical composition of the fluids being transported play a crucial role in this selection process.

Conclusion

API 5CT tubing couplings are vital components in the oil and gas industry, serving as the backbone for fluid transportation from subsurface formations to the surface. Understanding their specifications, types, and the importance of their role in maintaining well integrity can help industry professionals make informed decisions about their use. As the industry continues to evolve, adhering to API standards and investing in high-quality materials will remain critical for ensuring safety, efficiency, and sustainability in oil and gas operations. With the right technologies and practices, the performance of tubing couplings can be maximized, ultimately enhancing the overall productivity of oil and gas wells.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025