- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jún . 26, 2024 16:16

Back to list

Oil Well Tubing and Casing An Essential Guide to Petroleum Engineering

The Vital Role of Tubing and Casing in Oil and Gas Exploration

Tubing and casing are integral components in the complex world of oil and gas exploration and production. These steel pipes, though often unseen, play a pivotal role in ensuring the safe and efficient extraction of hydrocarbons from the earth's depths.

Tubing, typically smaller in diameter than casing, is inserted inside the casing and serves as a conduit for the upward flow of oil or gas from the reservoir to the surface. It's designed to withstand the internal pressure exerted by the produced fluids and the mechanical stresses caused by the pumping process. The tubing also protects the wellbore from damage and contamination, ensuring that the flow of hydrocarbons remains uninterrupted.

On the other hand, casing is the larger diameter pipe that forms the structural integrity of the well. It is cemented into place and serves as a barrier between different geological formations, preventing the unwanted mixing of fluids and potential environmental hazards. Casing is essential for maintaining wellbore stability, controlling subsurface pressures, and safeguarding against fluid migration. It's a critical component in preventing blowouts, an event that can have devastating consequences.

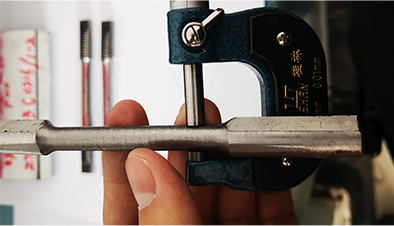

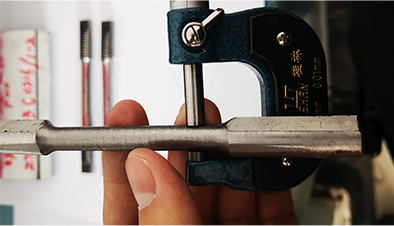

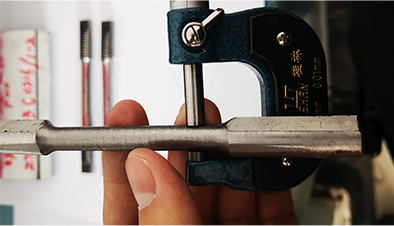

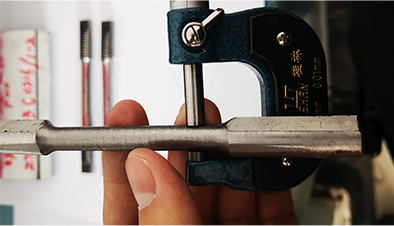

The selection of tubing and casing is a meticulous process, taking into account factors such as the depth of the well, the pressure and temperature conditions, the type of reservoir, and the expected production rate. The materials used, usually carbon or alloy steel, are chosen for their strength, durability, and resistance to corrosion.

Installation of tubing and casing is a multi-step operation known as 'running casing

Installation of tubing and casing is a multi-step operation known as 'running casing Installation of tubing and casing is a multi-step operation known as 'running casing

Installation of tubing and casing is a multi-step operation known as 'running casing

Installation of tubing and casing is a multi-step operation known as 'running casing

Installation of tubing and casing is a multi-step operation known as 'running casing tubing and casing.' After drilling to a certain depth, the drill string is removed, and the casing is lowered into the wellbore. Cement is then pumped down the annulus (the space between the casing and the wellbore) and allowed to set, creating a seal between the casing and the surrounding rock formation. Once this is complete, the tubing is subsequently installed.

Innovations in tubing and casing technology have significantly contributed to the advancement of the oil and gas industry. Lightweight materials, improved thread designs, and specialized coatings have all enhanced the performance and longevity of these pipes. Additionally, advancements in smart casing and tubing, equipped with sensors and communication capabilities, allow for real-time monitoring of well conditions, enhancing operational efficiency and safety.

In conclusion, tubing and casing are more than just steel conduits; they are the backbone of the oil and gas extraction process. Their role, from providing structural integrity to protecting the environment, cannot be overstated. As the industry continues to evolve, so too will the technology behind these vital components, ensuring the continued safe and effective extraction of the world's energy resources.

tubing and casing.' After drilling to a certain depth, the drill string is removed, and the casing is lowered into the wellbore. Cement is then pumped down the annulus (the space between the casing and the wellbore) and allowed to set, creating a seal between the casing and the surrounding rock formation. Once this is complete, the tubing is subsequently installed.

Innovations in tubing and casing technology have significantly contributed to the advancement of the oil and gas industry. Lightweight materials, improved thread designs, and specialized coatings have all enhanced the performance and longevity of these pipes. Additionally, advancements in smart casing and tubing, equipped with sensors and communication capabilities, allow for real-time monitoring of well conditions, enhancing operational efficiency and safety.

In conclusion, tubing and casing are more than just steel conduits; they are the backbone of the oil and gas extraction process. Their role, from providing structural integrity to protecting the environment, cannot be overstated. As the industry continues to evolve, so too will the technology behind these vital components, ensuring the continued safe and effective extraction of the world's energy resources.

Installation of tubing and casing is a multi-step operation known as 'running casing

Installation of tubing and casing is a multi-step operation known as 'running casing

Installation of tubing and casing is a multi-step operation known as 'running casing

Installation of tubing and casing is a multi-step operation known as 'running casing tubing and casing.' After drilling to a certain depth, the drill string is removed, and the casing is lowered into the wellbore. Cement is then pumped down the annulus (the space between the casing and the wellbore) and allowed to set, creating a seal between the casing and the surrounding rock formation. Once this is complete, the tubing is subsequently installed.

Innovations in tubing and casing technology have significantly contributed to the advancement of the oil and gas industry. Lightweight materials, improved thread designs, and specialized coatings have all enhanced the performance and longevity of these pipes. Additionally, advancements in smart casing and tubing, equipped with sensors and communication capabilities, allow for real-time monitoring of well conditions, enhancing operational efficiency and safety.

In conclusion, tubing and casing are more than just steel conduits; they are the backbone of the oil and gas extraction process. Their role, from providing structural integrity to protecting the environment, cannot be overstated. As the industry continues to evolve, so too will the technology behind these vital components, ensuring the continued safe and effective extraction of the world's energy resources.

tubing and casing.' After drilling to a certain depth, the drill string is removed, and the casing is lowered into the wellbore. Cement is then pumped down the annulus (the space between the casing and the wellbore) and allowed to set, creating a seal between the casing and the surrounding rock formation. Once this is complete, the tubing is subsequently installed.

Innovations in tubing and casing technology have significantly contributed to the advancement of the oil and gas industry. Lightweight materials, improved thread designs, and specialized coatings have all enhanced the performance and longevity of these pipes. Additionally, advancements in smart casing and tubing, equipped with sensors and communication capabilities, allow for real-time monitoring of well conditions, enhancing operational efficiency and safety.

In conclusion, tubing and casing are more than just steel conduits; they are the backbone of the oil and gas extraction process. Their role, from providing structural integrity to protecting the environment, cannot be overstated. As the industry continues to evolve, so too will the technology behind these vital components, ensuring the continued safe and effective extraction of the world's energy resources. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products