- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- ინგლისური

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

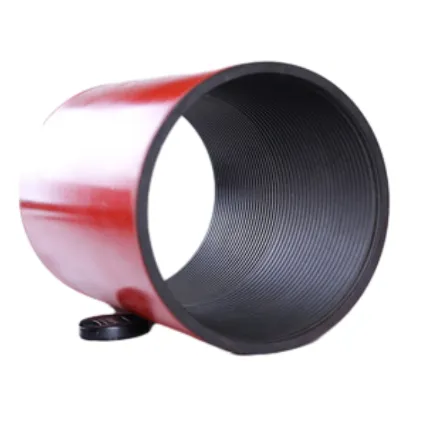

Application of Coupling Casing in Various Scenarios

Coupling casing is an important engineering component widely used in various industrial fields, including petroleum, natural gas, construction, and water conservancy. The main function of this equipment is to connect and protect pipelines, equipment, and mechanical components to ensure the safety and stability of the system under high pressure, high temperature, and other harsh environments. With the advancement of technology and the demand for industrial development, the application scenarios of casing coupling have become increasingly diverse. This article will explore its specific applications in different fields and the advantages it brings.

Coupling casing is widely used in drilling operations in the oil and gas industry

During the drilling process, the well casing coupler is used to connect the drilling pipe to the wellbore, providing support and protection for the wellbore. By providing a sturdy structure, coupling winding can prevent wellbore collapse and ensure the continuous progress of drilling. In addition, Coupling casing can effectively prevent fluid leakage, protect the surrounding environment, and prevent pollution from occurring. Therefore, the crucial role of Coupling casing in the oil and gas industry is self-evident.

In the construction industry, coupling winding is used for the protection of various piping systems, such as water pipes, gas supply pipelines, and power cables

By using coupling winding at pipeline connections, it is possible to effectively prevent pipeline damage caused by external forces. In addition, Coupling casing can also resist the effects of corrosion and environmental factors, extending the service life of pipelines. Meanwhile, in building structures, Coupling casing can also be used for the construction of large facilities such as bridges and tunnels, playing a role in enhancing the stability and load-bearing capacity of the structure.

Coupling and cash also play an important role in hydraulic engineering

It is mainly used for connecting and protecting reservoirs and channels to ensure smooth water circulation and management. Coupling casing ensures the safety and efficiency of hydraulic facilities by establishing a secure connection to prevent pipeline rupture caused by excessive water flow pressure. In addition, Coupling casing can effectively prevent leakage and improve the operational efficiency of the entire system in flood control and drainage systems.

With the development of new materials and technologies, the performance of coupling and winding continues to improve, making its application in the above-mentioned fields more extensive and in-depth

For example, by using high-strength alloy materials and advanced manufacturing processes, it is possible to produce more lightweight and robust coupling winding products that can adapt to more extreme operating environments. At the same time, intelligent Coupling casing is increasingly valued in monitoring and maintenance. Through built-in sensors and data analysis technology, real-time monitoring of equipment status can be achieved, improving the automation and intelligence level of the system.

In summary, Coupling casing, as an indispensable engineering component, plays a crucial role in multiple fields such as petroleum, construction, and water conservancy. With the continuous advancement of technology and the expansion of application scenarios, its importance will become increasingly prominent. In the future development, the design and application of Coupling casing will pay more attention to environmental protection, efficiency, and intelligence, further promoting the sustainable development of various industries.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockსიახლეებიNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsსიახლეებიNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipსიახლეებიNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipსიახლეებიNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryსიახლეებიNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryსიახლეებიNov.03,2025