- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1 2 npt stainless steel coupling

Understanding 1% 202 NPT Stainless Steel Couplings

Stainless steel couplings play a critical role in various industrial and plumbing applications due to their strength, durability, and resistance to corrosion. One type of coupling that has garnered particular attention is the 1% 202 NPT (National Pipe Thread) stainless steel coupling. This article explores the characteristics, applications, benefits, and installation of these couplings.

What is 1% 202 Stainless Steel?

The term 1% 202 refers to a specific grade of stainless steel known for its unique composition. Unlike common stainless steel grades such as 304 or 316, Type 202 stainless steel contains higher levels of manganese and lower levels of nickel. This adjustment not only provides cost advantages compared to more expensive alloy grades but also maintains good corrosion resistance and strength under various conditions.

One of the standout features of 202 stainless steel is its ability to resist oxidation, making it suitable for many different environments, including those involving heat and humidity. This is particularly important in industries such as food processing, oil and gas, and wastewater management where exposure to corrosive substances is common.

What is NPT?

NPT, or National Pipe Thread, is a US standard for tapered threads used on threaded pipes and fittings. The tapered design allows for a tighter seal as threads are engaged, reducing the likelihood of leaks. NPT is widely used in North America for various piping systems, making it essential for professionals in plumbing and industrial maintenance to be familiar with this threading standard.

Benefits of 1% 202 NPT Stainless Steel Couplings

1. Corrosion Resistance As mentioned, 202 stainless steel is resistant to rust and corrosion, which extends the lifespan of couplings used in outdoor or industrial settings where moisture is prevalent.

2. Strength and Durability These couplings exhibit high tensile strength, making them suitable for high-pressure applications. Their durability ensures that they can withstand harsh operational conditions.

3. Cost-Effectiveness Compared to higher grades of stainless steel, 1% 202 offers a more cost-effective solution while still providing good performance in many applications. This makes it ideal for budget-conscious projects without compromising quality.

4. Versatility 1% 202 NPT stainless steel couplings can be used in various applications, including water supply lines, gas lines, and other fluid transfer systems. Their versatility allows engineers and designers to integrate them across different systems seamlessly.

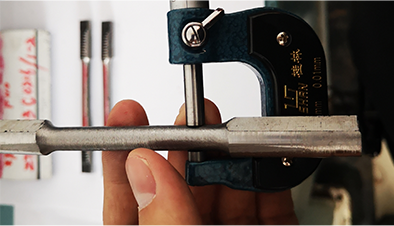

1 2 npt stainless steel coupling

Applications

The applications of 1% 202 NPT stainless steel couplings are vast, covering multiple industries

- Plumbing Used in residential and commercial plumbing systems for connecting pipes, valves, and fittings. - Oil and Gas Essential in the oil and gas supply chain for transferring fluids efficiently and safely. - Food and Beverage Safe for use in hygienic processes due to its non-reactive properties. - Chemical Processing Provides compatibility with various chemicals, making it a reliable choice in this sector.

Installation Tips

1. Preparation Always inspect the coupling and the connecting pipe for damage prior to installation. Ensure threads are clean and free from debris.

2. Alignment Make sure the pipes are properly aligned to prevent undue stress, which can lead to leaks.

3. Torque Specifications Follow manufacturer specifications for torque settings to avoid over-tightening, which can strip the threads or crack the fitting.

4. Sealants Although NPT threads create a tight seal, using Teflon tape can help ensure a leak-proof connection.

Conclusion

The 1% 202 NPT stainless steel coupling is a vital component in many industrial and plumbing applications. Its corrosion resistance, strength, cost-effectiveness, versatility, and ease of installation make it a preferred choice for professionals. Understanding its features and proper installation can lead to improved performance and longevity in various systems. As industries continue to evolve, the significance of such fittings will only increase, underscoring the need for reliability in infrastructure and design.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025