- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 06, 2025 06:15

Back to list

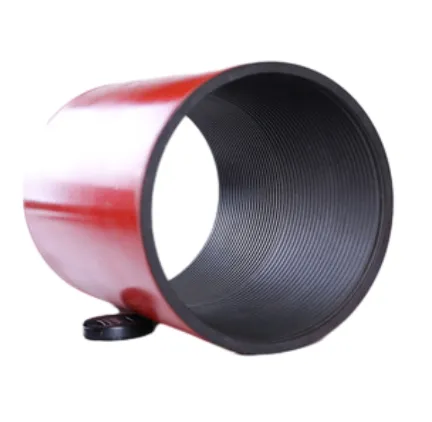

Tubing Coupling

When it comes to selecting high-quality components for industrial applications, one cannot overlook the significance of stainless steel couplings. These connectors, often underestimated, play a pivotal role in ensuring the seamless integration of various machinery and pipeline systems, leading to optimal performance and longevity. Understanding their benefits, applications, and the technology behind them will help businesses make informed decisions.

In terms of authoritativeness, various standards govern the production and application of stainless steel couplings. Familiarity with standards such as ASTM, ANSI, and ISO ensures that the chosen components meet international quality benchmarks. Additionally, manufacturers with certifications from recognized bodies are generally more trustworthy, as these certifications demonstrate adherence to stringent quality control processes. Trustworthiness in choosing stainless steel couplings also involves sourcing them from reputable suppliers with a proven track record. Reviews and testimonials from existing clients can provide insights into the supplier’s reliability and product quality. Furthermore, suppliers offering comprehensive warranties and after-sales support instill confidence in the durability and performance of the couplings. Finally, adopting stainless steel couplings aligns with modern trends in sustainable industrial practices. Stainless steel is recyclable, and its longevity reduces waste and the carbon footprint associated with frequent replacements. This environmental consideration not only meets regulatory requirements but also reflects a company’s commitment to sustainable operations, enhancing its reputation and appeal to eco-conscious stakeholders. In conclusion, stainless steel couplings offer undeniable advantages that make them a preferred choice in many industrial settings. Their durability, resistance to extreme conditions, and alignment with sustainable practices underscore their value. By leveraging expertise in material selection, design considerations, and industry standards, businesses can ensure they select the most appropriate coupling for their specific needs, ultimately driving efficiency and reliability in their operations.

In terms of authoritativeness, various standards govern the production and application of stainless steel couplings. Familiarity with standards such as ASTM, ANSI, and ISO ensures that the chosen components meet international quality benchmarks. Additionally, manufacturers with certifications from recognized bodies are generally more trustworthy, as these certifications demonstrate adherence to stringent quality control processes. Trustworthiness in choosing stainless steel couplings also involves sourcing them from reputable suppliers with a proven track record. Reviews and testimonials from existing clients can provide insights into the supplier’s reliability and product quality. Furthermore, suppliers offering comprehensive warranties and after-sales support instill confidence in the durability and performance of the couplings. Finally, adopting stainless steel couplings aligns with modern trends in sustainable industrial practices. Stainless steel is recyclable, and its longevity reduces waste and the carbon footprint associated with frequent replacements. This environmental consideration not only meets regulatory requirements but also reflects a company’s commitment to sustainable operations, enhancing its reputation and appeal to eco-conscious stakeholders. In conclusion, stainless steel couplings offer undeniable advantages that make them a preferred choice in many industrial settings. Their durability, resistance to extreme conditions, and alignment with sustainable practices underscore their value. By leveraging expertise in material selection, design considerations, and industry standards, businesses can ensure they select the most appropriate coupling for their specific needs, ultimately driving efficiency and reliability in their operations.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products