- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

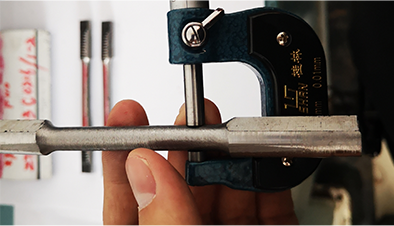

3 8 stainless steel coupling

The Versatility and Strength of 3% 208% Stainless Steel Couplings

In the modern world of engineering and construction, materials play a pivotal role in determining the performance, reliability, and durability of various components. Among these materials, stainless steel has emerged as a preferred choice due to its exceptional resistance to corrosion, impressive strength-to-weight ratio, and longevity. One specific grade of stainless steel that has garnered attention is the 3% 208% stainless steel, particularly in the realm of couplings.

What are Stainless Steel Couplings?

Stainless steel couplings are mechanical components utilized to join two shafts together, allowing for the transfer of torque and motion between them. They are widely employed in various applications, ranging from industrial machinery to automotive systems and water treatment facilities. The choice of material for couplings is crucial, as they must withstand the forces and conditions they encounter, including vibration, temperature fluctuations, and exposure to corrosive environments.

The Unique Properties of 3% 208% Stainless Steel

3% 208% stainless steel is a specific alloy that combines various elements to enhance its properties. The primary constituents include nickel, chromium, and molybdenum, which contribute to its high resistance to oxidation and corrosion. Additionally, the specific percentages of elements provide the alloy with unique mechanical properties that make it suitable for high-stress applications.

The key benefits of using 3% 208% stainless steel in couplings include

1. Corrosion Resistance One of the most significant advantages of stainless steel is its ability to resist rust and corrosion. This makes 3% 208% stainless steel couplings ideal for use in harsh environments, including marine applications and chemical processing industries.

3 8 stainless steel coupling

2. High Strength Couplings made from this material can bear substantial loads without deforming or failing. Their high tensile strength ensures reliable performance in demanding applications, such as heavy machinery and automotive systems.

3. Durability and Longevity The inherent properties of stainless steel, coupled with its resistance to wear and tear, ensure that 3% 208% stainless steel couplings have an extended service life. This durability translates to lower maintenance costs and fewer replacements over time.

4. Versatility These couplings are available in various designs and sizes, making them suitable for a wide range of applications. Whether for connecting motors, pumps, or other rotating equipment, 3% 208% stainless steel couplings provide a reliable solution.

Application Areas

3% 208% stainless steel couplings are employed across diverse industries. In the automotive sector, they are utilized in drivetrains to connect engine and transmission shafts. In manufacturing, these couplings are indispensable in conveyor systems, pumps, and compressors, ensuring smooth operation and efficient power transfer. Furthermore, in the oil and gas sector, their ability to withstand corrosive environments makes them a perfect choice for pipeline applications.

Conclusion

In conclusion, the use of 3% 208% stainless steel couplings exemplifies the advancements in material science that enhance the performance and reliability of mechanical systems. Their exceptional corrosion resistance, high strength, durability, and versatility make them an indispensable choice for numerous industrial applications. As industries continue to evolve, the demand for reliable, high-performance components like 3% 208% stainless steel couplings will undoubtedly grow, solidifying their place at the forefront of engineering solutions.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025