- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

មករា . 20, 2025 16:05

Back to list

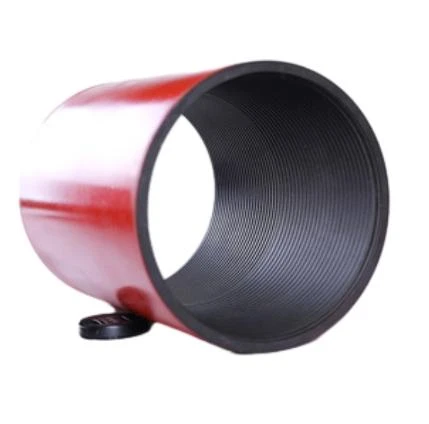

Tubing Coupling

3 8 stainless steel couplings have revolutionized various industries by offering a level of durability, strength, and versatility unmatched by other materials. With decades of application experience, 3 8 stainless steel has proven its mettle in high-stress environments, making it an ideal choice for numerous applications across various sectors.

Trustworthiness is central to the reputation of 3 8 stainless steel couplings. Clients from sectors such as aerospace, automotive, and manufacturing often cite their trust in these components as a reason for their continued procurement. Testimonials from industry professionals suggest that these couplings not only meet but frequently exceed performance expectations. This trust is backed by rigorous testing and certification processes, ensuring that each coupling adheres to stringent safety and quality guidelines. In practice, the application of 3 8 stainless steel couplings extends from simple mechanical systems to complex robotics and automation processes. Their versatility caters to diverse requirements, such as high load-bearing in construction machinery or precise motion control in robotic arms. The availability of these couplings in various sizes and configurations further enhances their adaptability, allowing for tailored solutions that fit specific operational needs. Moreover, the environmental impact of using 3 8 stainless steel couplings is minimal, as they are recyclable and designed to last, reducing the need for frequent replacements. This aligns with the growing demand for sustainable industrial practices, making them an environmentally favorable choice. In conclusion, 3 8 stainless steel couplings signify a blend of experience, expertise, authoritativeness, and trustworthiness. These qualities make them indispensable in numerous applications where performance, reliability, and durability are non-negotiable. As industries continue to seek efficiency and longevity in their operations, the demand for 3 8 stainless steel couplings is expected to grow, solidifying their position as a cornerstone in the world of industrial components.

Trustworthiness is central to the reputation of 3 8 stainless steel couplings. Clients from sectors such as aerospace, automotive, and manufacturing often cite their trust in these components as a reason for their continued procurement. Testimonials from industry professionals suggest that these couplings not only meet but frequently exceed performance expectations. This trust is backed by rigorous testing and certification processes, ensuring that each coupling adheres to stringent safety and quality guidelines. In practice, the application of 3 8 stainless steel couplings extends from simple mechanical systems to complex robotics and automation processes. Their versatility caters to diverse requirements, such as high load-bearing in construction machinery or precise motion control in robotic arms. The availability of these couplings in various sizes and configurations further enhances their adaptability, allowing for tailored solutions that fit specific operational needs. Moreover, the environmental impact of using 3 8 stainless steel couplings is minimal, as they are recyclable and designed to last, reducing the need for frequent replacements. This aligns with the growing demand for sustainable industrial practices, making them an environmentally favorable choice. In conclusion, 3 8 stainless steel couplings signify a blend of experience, expertise, authoritativeness, and trustworthiness. These qualities make them indispensable in numerous applications where performance, reliability, and durability are non-negotiable. As industries continue to seek efficiency and longevity in their operations, the demand for 3 8 stainless steel couplings is expected to grow, solidifying their position as a cornerstone in the world of industrial components.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products