- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

មិថុនា . 13, 2024 12:21

Back to list

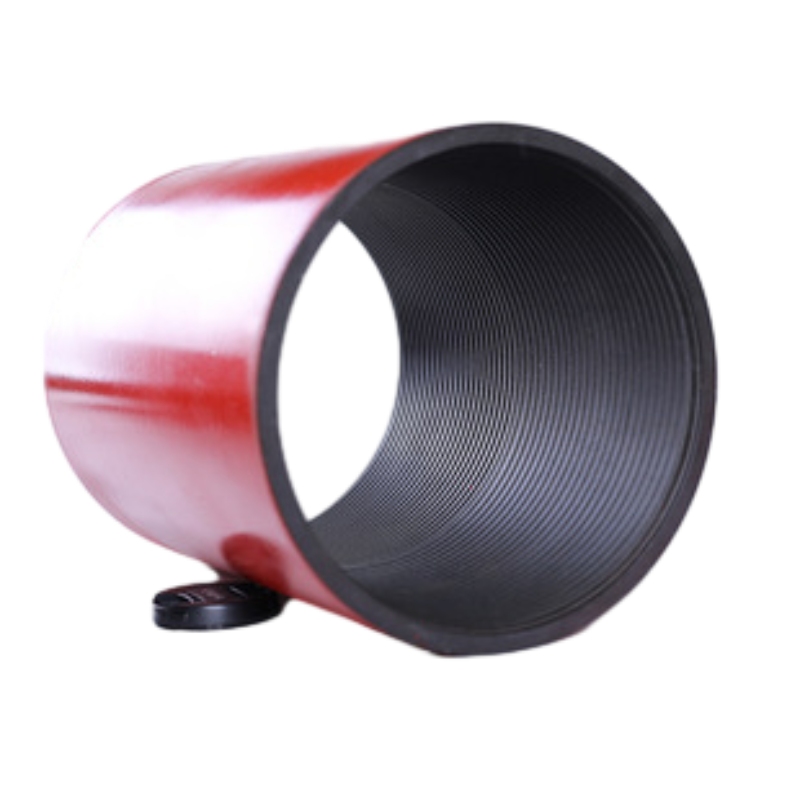

API 5CT coupling refers to a connector used in oil and gas industry pipes.

Understanding API 5CT Couplings A Vital Component in Oil and Gas Industry

API 5CT couplings, an integral part of the oil and gas industry's tubing and casing connections, play a crucial role in ensuring the structural integrity and efficient operation of subterranean well systems. The American Petroleum Institute (API) has established a set of rigorous standards, specifically API 5CT, to govern the design, manufacture, and testing of these couplings.

API 5CT, or the Specification for Casing and Tubing, is a comprehensive guideline that ensures the quality and performance of tubular goods used in drilling and production operations. The 'C' in 5CT stands for Casing, which is a large-diameter pipe used to support the wellbore, while 'T' signifies Tubing, which is employed to extract oil or gas from the reservoir. The coupling, connecting these tubes, is a critical element in maintaining the strength and sealing properties of the entire system.

API 5CT couplings are designed to withstand extreme conditions, such as high pressure, temperature fluctuations, and mechanical stress. They are manufactured from high-strength steel, providing resistance against corrosion and wear. These couplings are engineered with precision threads that allow for secure and leak-proof connections, minimizing the risk of well failures.

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions api 5ct coupling. It also outlines stringent testing requirements, including non-destructive tests, hydrostatic pressure tests, and tensile strength tests, to guarantee the reliability and durability of the couplings.

Moreover, API 5CT coupling designs incorporate features like pin and box threads, which not only ensure easy assembly but also provide a robust connection capable of withstanding the forces exerted during drilling and production processes. The thread design is a key factor, as it affects the torque and tension characteristics, thereby influencing the overall performance of the well.

In conclusion, API 5CT couplings are more than just connectors; they are the backbone of the tubular structure in oil and gas wells. Their adherence to API 5CT standards ensures safety, efficiency, and longevity in operations. As the oil and gas industry continues to evolve, so does the technology behind API 5CT couplings, constantly adapting to meet the demands of deeper wells, harsher environments, and increased productivity. Therefore, understanding and appreciating the significance of API 5CT couplings is vital for anyone involved in this dynamic sector.

api 5ct coupling. It also outlines stringent testing requirements, including non-destructive tests, hydrostatic pressure tests, and tensile strength tests, to guarantee the reliability and durability of the couplings.

Moreover, API 5CT coupling designs incorporate features like pin and box threads, which not only ensure easy assembly but also provide a robust connection capable of withstanding the forces exerted during drilling and production processes. The thread design is a key factor, as it affects the torque and tension characteristics, thereby influencing the overall performance of the well.

In conclusion, API 5CT couplings are more than just connectors; they are the backbone of the tubular structure in oil and gas wells. Their adherence to API 5CT standards ensures safety, efficiency, and longevity in operations. As the oil and gas industry continues to evolve, so does the technology behind API 5CT couplings, constantly adapting to meet the demands of deeper wells, harsher environments, and increased productivity. Therefore, understanding and appreciating the significance of API 5CT couplings is vital for anyone involved in this dynamic sector.

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions

The API 5CT standard specifies several grades of steel for couplings, each with its own mechanical properties tailored to specific well conditions api 5ct coupling. It also outlines stringent testing requirements, including non-destructive tests, hydrostatic pressure tests, and tensile strength tests, to guarantee the reliability and durability of the couplings.

Moreover, API 5CT coupling designs incorporate features like pin and box threads, which not only ensure easy assembly but also provide a robust connection capable of withstanding the forces exerted during drilling and production processes. The thread design is a key factor, as it affects the torque and tension characteristics, thereby influencing the overall performance of the well.

In conclusion, API 5CT couplings are more than just connectors; they are the backbone of the tubular structure in oil and gas wells. Their adherence to API 5CT standards ensures safety, efficiency, and longevity in operations. As the oil and gas industry continues to evolve, so does the technology behind API 5CT couplings, constantly adapting to meet the demands of deeper wells, harsher environments, and increased productivity. Therefore, understanding and appreciating the significance of API 5CT couplings is vital for anyone involved in this dynamic sector.

api 5ct coupling. It also outlines stringent testing requirements, including non-destructive tests, hydrostatic pressure tests, and tensile strength tests, to guarantee the reliability and durability of the couplings.

Moreover, API 5CT coupling designs incorporate features like pin and box threads, which not only ensure easy assembly but also provide a robust connection capable of withstanding the forces exerted during drilling and production processes. The thread design is a key factor, as it affects the torque and tension characteristics, thereby influencing the overall performance of the well.

In conclusion, API 5CT couplings are more than just connectors; they are the backbone of the tubular structure in oil and gas wells. Their adherence to API 5CT standards ensures safety, efficiency, and longevity in operations. As the oil and gas industry continues to evolve, so does the technology behind API 5CT couplings, constantly adapting to meet the demands of deeper wells, harsher environments, and increased productivity. Therefore, understanding and appreciating the significance of API 5CT couplings is vital for anyone involved in this dynamic sector. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products