- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding API Casing Sizes for Optimal Compatibility and Performance in Drilling Operations

Understanding API Casing Sizes A Comprehensive Overview

The American Petroleum Institute (API) has developed a standardized system for classifying casing sizes used in the oil and gas industry, which facilitates effective communication and ensures the safety and efficiency of drilling operations. Casing is essential in drilling projects as it provides structural integrity to wells, prevents the collapse of boreholes, and protects groundwater from contamination. Understanding API casing sizes, their designations, and applications is vital for professionals in the oil and gas sector.

What is API Casing?

API casing refers to the steel pipes that are installed in wells after drilling is completed. The main purpose of casing is to line the borehole, maintaining its shape and preventing the influx of unstable materials from the surrounding earth. The casing acts as a protective barrier, isolating different pressure zones and preventing oil, gas, or water from migrating vertically through the wellbore.

Casing Sizes and Designations

API casing sizes are designated by their nominal diameter, which is typically expressed in inches. The most commonly used casing sizes in the industry range from 4.5 inches to 20 inches. The designations include

- Surface Casing (e.g., 8.5” or 10.75”) This is the first casing installed and is crucial for protecting the freshwater aquifers. It prevents contamination and provides support for the upper section of the well. - Intermediate Casing (e.g., 9.625” or 11.75”) This is installed deeper in the well to isolate pressure zones and protect the wellbore from any challenges that may arise during production. It is often used in areas with challenging geological formations.

- Production Casing (e.g., 7” or 5.5”) This casing runs from the last set of casing to the total depth of the well. It is essential for the extraction of hydrocarbons and is designed to withstand the pressures and temperatures encountered during production.

Key Considerations in Casing Selection

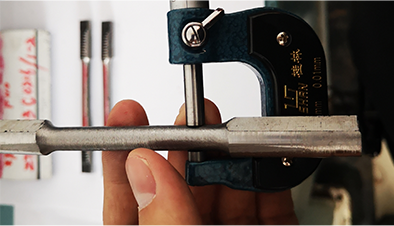

api casing sizes

Choosing the appropriate casing size is a critical aspect of well design and construction

. Several factors must be considered, including1. Well Depth The deeper the well, the larger the casing size needed to ensure stability and integrity.

2. Pressure and Temperature High-pressure wells require thicker wall casings to withstand the stress.

3. Geological Conditions Formations with unstable geology may require additional support through larger casing sizes or multiple casing strings.

4. Environmental Impact Casing selection must also consider the protection of surrounding environments, especially groundwater resources.

Conclusion

API casing sizes play a fundamental role in the successful operation of oil and gas wells. Understanding the specifications and implications of different casing sizes aids engineers and geologists in making informed decisions that align with safety standards and operational efficiency. As the industry continues to evolve, advancements in casing technology and materials will further enhance the effectiveness of these essential components. By staying abreast of API standards and embracing innovations, professionals can contribute to more reliable and environmentally responsible drilling practices.

Overall, a solid grasp of API casing sizes is indispensable for anyone involved in the drilling and production phases of oil and gas extraction, ensuring that projects are conducted safely, efficiently, and responsibly.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025