- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កក្កដា . 10, 2024 20:35

Back to list

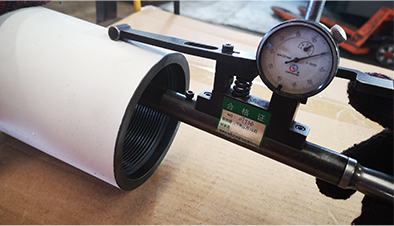

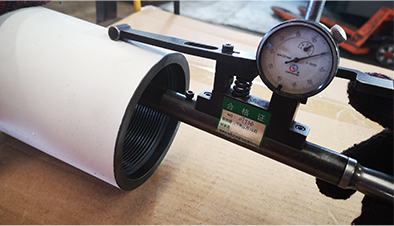

Seating nipple tubing functions, installation, and maintenance in oil and gas wells.

Seating nipple tubing is a crucial component in the oil and gas industry, playing a key role in the production and transportation of oil and gas from wells. This type of tubing is specifically designed to connect various pieces of equipment in the wellbore, allowing for the safe and efficient extraction of oil and gas.

One of the main functions of seating nipple tubing is to provide a secure connection between the production tree at the surface and the downhole tools in the wellbore. This connection is essential for controlling the flow of oil and gas from the reservoir to the surface, as well as for monitoring and regulating the production process. The seating nipple tubing is typically threaded on both ends, allowing for easy installation and removal during well maintenance activities.

In addition to its role in connecting downhole tools and surface equipment, seating nipple tubing also helps to protect the wellbore and prevent leaks or blowouts. By providing a sealed connection between different components, the tubing helps to maintain the integrity of the well and prevent the escape of oil and gas into the surrounding environment. This is particularly important in offshore drilling operations, where the risk of spills and leaks can have serious environmental consequences.

Seating nipple tubing is typically made from high-quality steel or other durable materials that can withstand the harsh conditions encountered in oil and gas wells

seating nipple tubing. These materials are chosen for their ability to resist corrosion, erosion, and high temperatures, ensuring that the tubing remains functional and reliable over the long term. Additionally, the tubing is often coated or lined with special materials to further enhance its durability and performance. Proper installation and maintenance of seating nipple tubing are essential for ensuring the safety and efficiency of oil and gas production operations. Regular inspections and testing should be conducted to detect any signs of wear or damage, and repairs or replacements should be made as needed to prevent accidents or production disruptions. By investing in high-quality seating nipple tubing and following best practices for installation and maintenance, oil and gas operators can help to ensure the long-term success of their production operations. In conclusion, seating nipple tubing plays a critical role in the oil and gas industry, providing a secure connection between downhole tools and surface equipment and helping to protect the wellbore from leaks and blowouts. By using high-quality materials and following best practices for installation and maintenance, operators can ensure the safety and efficiency of their production operations. Investing in seating nipple tubing is a smart choice for any oil and gas company looking to maximize the productivity and profitability of their wells.

seating nipple tubing. These materials are chosen for their ability to resist corrosion, erosion, and high temperatures, ensuring that the tubing remains functional and reliable over the long term. Additionally, the tubing is often coated or lined with special materials to further enhance its durability and performance. Proper installation and maintenance of seating nipple tubing are essential for ensuring the safety and efficiency of oil and gas production operations. Regular inspections and testing should be conducted to detect any signs of wear or damage, and repairs or replacements should be made as needed to prevent accidents or production disruptions. By investing in high-quality seating nipple tubing and following best practices for installation and maintenance, oil and gas operators can help to ensure the long-term success of their production operations. In conclusion, seating nipple tubing plays a critical role in the oil and gas industry, providing a secure connection between downhole tools and surface equipment and helping to protect the wellbore from leaks and blowouts. By using high-quality materials and following best practices for installation and maintenance, operators can ensure the safety and efficiency of their production operations. Investing in seating nipple tubing is a smart choice for any oil and gas company looking to maximize the productivity and profitability of their wells.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products