- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

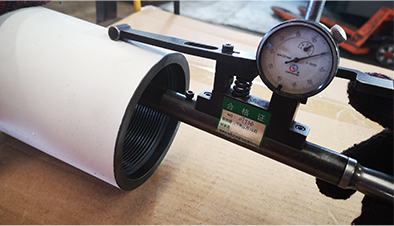

seating nipple in tubing

Understanding the Importance of Seating Nipple in Tubing

In the oil and gas industry, the effective transportation of fluids is paramount to operational success. Among various components used in the well completion and production processes, the seating nipple plays a critical role in the functionality of tubing systems. This article delves into the significance of the seating nipple, its design, and the advantages it offers in optimizing fluid flow.

What is a Seating Nipple?

A seating nipple is a specialized component installed in the tubing string of a well. Its primary function is to securely latch on to downhole tools such as plugs, packers, or other completion equipment. The design of a seating nipple allows it to create a strong mechanical and hydraulic connection, ensuring the proper functioning of the downhole equipment during various operational phases.

Seating nipples come with specific dimensional specifications and profiles, which are tailored to accommodate various types of tools used in oil and gas operations. They can be classified based on their designs, such as profile nipples, that correspond to specific tool types, enabling a seamless attachment during operations.

Importance in Tubing Systems

The seating nipple's role in tubing systems extends beyond mere attachment and detachment. A well-designed seating nipple can significantly enhance the operational efficiency and safety of a well. When a downhole tool is seated properly in a nipple, it minimizes the risk of shifting or unseating due to pressure changes or other dynamic factors within the wellbore.

Moreover, the proper seating of a nipple ensures that fluid can flow freely past the tool when necessary, facilitating efficient production and reducing the risk of blockages. In scenarios where a tool needs to be retrieved or replaced, a reliable seating nipple enables quick and safe disengagement, reducing non-productive time (NPT) during operations.

seating nipple in tubing

Advantages of Seating Nipples

2. Operational Efficiency By providing a robust connection, seating nipples allow for optimized fluid flow and are crucial when performing tasks such as well testing and production enhancement.

3. Cost-Effectiveness Minimizing the risk of tool failure not only enhances safety but also leads to significant cost savings by reducing downtime and preventing the costly process of redeployment.

4. Safety Assurance The robust nature of seating nipples provides an added layer of safety, ensuring that tools remain securely in place under varying pressure conditions.

5. Versatility Many modern seating nipples are designed to be compatible with a range of tools and applications, offering flexibility in choosing equipment based on specific operational requirements.

Conclusion

The seating nipple in tubing systems is an essential component that plays a crucial role in the efficiency and safety of oil and gas operations. By ensuring reliable connections for downhole tools, seating nipples optimize fluid movement, enhance operational safety, and contribute to the overall productivity of well operations. As the industry continues to evolve, understanding and implementing effective seating nipple designs will remain integral to successful extraction and production processes. Investing in high-quality seating nipples is a small but significant step toward improving the resilience and effectiveness of oil and gas operations.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025