- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

stainless steel coupling 3 4

Understanding Stainless Steel Couplings A Focus on 3 and 4 Options

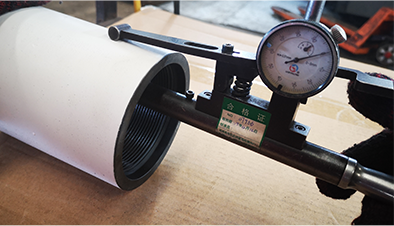

Stainless steel couplings are essential components employed in various industrial applications, particularly in piping and plumbing systems. Their primary role is to connect two pieces of pipe or tubing, facilitating the seamless transfer of fluids or gases in a secure and efficient manner. This article delves into the significance of stainless steel couplings, specifically focusing on the 3-inch and 4-inch sizes, exploring their advantages, applications, and considerations for selection.

What Are Stainless Steel Couplings?

Stainless steel couplings are fittings designed to join two segments of pipe. They are manufactured using high-grade stainless steel, known for its superior corrosion resistance, durability, and aesthetic appeal. The material is particularly effective in harsh environments, such as chemical processing plants, food and beverage production, and marine applications, where exposure to moisture and corrosive elements is common.

Advantages of Stainless Steel Couplings

1. Corrosion Resistance One of the most compelling advantages of stainless steel is its excellent resistance to corrosion. This property is crucial in extending the lifespan of piping systems, reducing maintenance costs, and ensuring safety in operations. Couplings made from stainless steel can withstand various environmental factors, making them ideal for outdoor and industrial applications.

2. Strength and Durability Stainless steel is known for its impressive strength-to-weight ratio. Couplings made from this material can handle high pressure and temperature fluctuations without compromising performance. This characteristic is vital in applications involving steam, gas, or high-temperature liquids.

3. Hygienic Properties In industries such as food processing and pharmaceuticals, hygiene is paramount. The smooth surface of stainless steel couplings prevents bacteria build-up, ensuring that the transported substances remain uncontaminated. This attribute makes them a preferred choice for sanitary applications.

4. Ease of Installation Stainless steel couplings, particularly those in 3 and 4 sizes, are designed for easy installation. Various connection styles, such as threaded, welded, or flanged, cater to different system requirements. Many of these couplings come with pre-installed seals or gaskets that enhance leak prevention.

Applications of 3 and 4 Stainless Steel Couplings

Stainless steel couplings are widely used in many sectors, including

- Water Treatment In municipal water treatment facilities, 3 and 4 couplings help to connect pipes that transport purified water, ensuring a reliable flow.

stainless steel coupling 3 4

- Oil and Gas The oil and gas industry often employs stainless steel couplings to connect pipelines because of their resistance to corrosive hydrocarbons and their capacity to withstand high pressures

.- Food and Beverage Production In this sector, 3 and 4 couplings enable efficient transport of ingredients and products through piping systems, maintaining the high hygiene standards required.

- Pharmaceuticals Sterile processes in pharmaceutical plants rely on reliable connections that prevent contamination, making stainless steel couplings a preferred option.

Selecting the Right Coupling

When choosing between 3-inch and 4-inch stainless steel couplings, several factors should be considered

1. Pipe Size and Compatibility The first step is to identify the size of the pipes that need connection. Ensuring that the coupling matches the pipe diameter is crucial for an effective seal.

2. Pressure and Temperature Ratings Depending on the application, it’s important to check the pressure and temperature ratings of the couplings. Ensure that they meet or exceed the conditions under which they will operate.

3. Type of Connection Consider the type of connection required (threaded, welded, etc.). Some applications may benefit from the robustness of welded couplings, while others may require the flexibility of threaded connections.

4. Regulatory Compliance In industries like food and pharmaceuticals, regulatory compliance with health and safety standards is critical. Ensure that your selected couplings meet the relevant certifications.

Conclusion

Stainless steel couplings, particularly in 3-inch and 4-inch sizes, are vital components in many industrial systems. Their corrosion resistance, durability, and versatility make them suitable for a wide range of applications. By understanding their properties and applications, users can effectively choose the right couplings to ensure seamless operations in their piping systems. Whether in the oil and gas industry, food production, or municipal water systems, stainless steel couplings continue to play an essential role in facilitating connectivity and efficiency.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025