- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

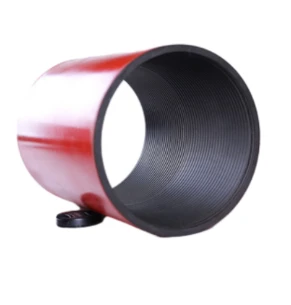

Threaded Bull Plug for Enhanced Performance and Durability in Industrial Applications

Understanding the Threaded Bull Plug A Comprehensive Guide

In the world of plumbing and piping, proper sealing and connection methods are vital. Among the numerous types of fittings available, the bull plug stands out due to its specific functionality. This article will delve into the intricacies of the threaded bull plug, exploring its design, applications, advantages, and installation tips.

What is a Threaded Bull Plug?

A threaded bull plug is a type of pipe fitting designed to close off the end of a pipe or a fitting. The term bull plug refers to its shape, which resembles a bull's nose. Threaded bull plugs typically feature male or female threads, allowing them to be securely screwed into corresponding threaded openings in pipes or fittings. They are commonly made from durable materials such as brass, stainless steel, or PVC, ensuring longevity and reliability in various environments.

Key Features and Materials

The construction of a threaded bull plug is critical to its performance. The choice of material influences factors such as corrosion resistance, pressure tolerance, and compatibility with different substances. Brass bull plugs are renowned for their strength and resistance to corrosion, making them an excellent choice for water supply lines. Stainless steel options provide even greater resistance to rust and are preferred in industrial settings where harsh chemicals may be present. PVC bull plugs, on the other hand, are lightweight and resistant to corrosion, making them ideal for applications involving chemicals.

The threads on a bull plug need to be uniform and well-crafted to ensure a tight seal. A proper seal prevents leaks, which can lead to pressure loss and potential damage to systems. This is why understanding the threading standards, such as NPT (National Pipe Tapered) or BSP (British Standard Pipette), is essential when selecting a bull plug.

Applications of Threaded Bull Plugs

Threaded bull plugs find their use across a wide range of applications

1. Water Systems In residential plumbing, they are often used to cap off unused lines or fittings, ensuring that water flows only where intended.

2. Industrial Applications In factories, threaded bull plugs are utilized in systems that require regular alterations or maintenance, allowing easy access and closure without compromising the system's integrity.

3. Oil and Gas Industry In this sector, bull plugs are essential for securing pipe ends and ensuring safety in various operations, including drilling and transport.

threaded bull plug

Advantages of Using Threaded Bull Plugs

1. Versatility Their availability in different sizes and materials makes threaded bull plugs suitable for various applications, from residential plumbing to industrial uses.

2. Ease of Installation Installing a threaded bull plug is straightforward. The corresponding pipe thread simply needs to be cleaned, threaded in the bull plug, and tightened.

3. Effective Sealing When properly installed, threaded bull plugs provide a reliable seal, preventing leaks and maintaining system pressure.

4. Cost-Effective Generally, bull plugs are inexpensive components that offer effective solutions for piping needs.

Installation Tips

Correct installation is crucial for the efficacy of bull plugs. Here are some steps to ensure proper installation

- Select the Right Size Measure the diameter of the pipe or fitting to choose a bull plug that fits seamlessly. - Apply Thread Sealant For added security against leaks, consider applying thread sealant tape or compound to the threads before installation.

- Hand-Tighten First Start by hand-tightening the bull plug to avoid cross-threading.

- Use a Wrench for Final Tightening Once hand-tightened, use an appropriate wrench to apply additional torque, being cautious not to overtighten as this could damage the threads.

- Check for Leaks After installation, always run a test to check for leaks. If any are detected, further tightening or re-installation may be necessary.

Conclusion

The threaded bull plug is a simple yet essential component in the complex world of plumbing and industrial systems. Its reliable sealing capabilities, ease of use, and adaptability across various materials make it indispensable in numerous applications. By understanding its features, benefits, and installation methods, users can effectively incorporate threaded bull plugs into their plumbing or industrial setups, ensuring efficiency and safety in their operations.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025