- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ມ.ກ. . 21, 2025 04:00

Back to list

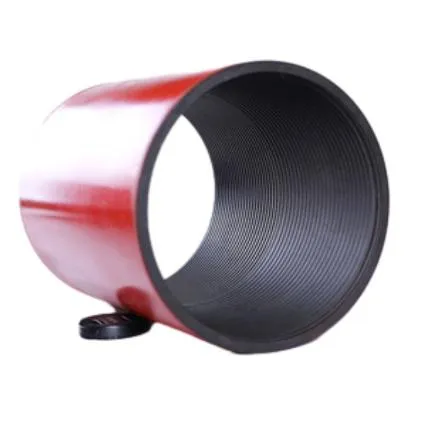

wholesale api threading casing coupling

A comprehensive API tubing and casing chart serves as a critical reference for professionals in the oil and gas industry. Whether you're involved in drilling, production or supply chain, understanding the specifications and applications of different tubing and casing sizes can significantly impact operational efficiency and safety. Here, we delve into the intricacies of these essential tools, offering insights garnered from extensive field experience and industry expertise, to build trust and authority on the subject.

Moreover, sustainable and ethical sourcing of materials has taken center stage in recent years, reflecting a shift in industry priorities. Clients now demand transparency, not only in product specifications but also in production methods that align with environmental standards. As such, manufacturers are increasingly held accountable for their supply chains, reflecting a more responsible approach towards resource utilization. The global nature of the oil and gas sector necessitates an understanding of international standards and collaboration. API specifications often align with global practices, facilitating seamless integration of U.S. technologies with operations worldwide. This authority on the international stage is testament to API's rigorous standard-setting processes. In practice, leveraging the insights from an API tubing and casing chart requires a blend of theoretical knowledge and practical application. Engineers must not only interpret data but must also apply their findings to real-world scenarios, calibrating their choices based on firsthand experiences and problem-solving skills honed through years of on-site challenges. Safety is paramount, and working knowledge of API specifications aids in predictive maintenance and proactive problem-solving. Understanding how different grades respond to specific scenarios allows for preemptive adjustments, significantly reducing the risk of blowouts or other catastrophic failures. In conclusion, an API tubing and casing chart is not merely a tool but a cornerstone of industry expertise, providing a critical pathway to operational excellence. Its effective use ensures the safe and efficient extraction of resources, reaffirming the industry's commitment to quality and reliability. For professionals entrenched in the oil and gas sector, these charts encapsulate a world of pivotal information, their trusted authority reinforcing decisions that shape the energy landscapes of tomorrow.

Moreover, sustainable and ethical sourcing of materials has taken center stage in recent years, reflecting a shift in industry priorities. Clients now demand transparency, not only in product specifications but also in production methods that align with environmental standards. As such, manufacturers are increasingly held accountable for their supply chains, reflecting a more responsible approach towards resource utilization. The global nature of the oil and gas sector necessitates an understanding of international standards and collaboration. API specifications often align with global practices, facilitating seamless integration of U.S. technologies with operations worldwide. This authority on the international stage is testament to API's rigorous standard-setting processes. In practice, leveraging the insights from an API tubing and casing chart requires a blend of theoretical knowledge and practical application. Engineers must not only interpret data but must also apply their findings to real-world scenarios, calibrating their choices based on firsthand experiences and problem-solving skills honed through years of on-site challenges. Safety is paramount, and working knowledge of API specifications aids in predictive maintenance and proactive problem-solving. Understanding how different grades respond to specific scenarios allows for preemptive adjustments, significantly reducing the risk of blowouts or other catastrophic failures. In conclusion, an API tubing and casing chart is not merely a tool but a cornerstone of industry expertise, providing a critical pathway to operational excellence. Its effective use ensures the safe and efficient extraction of resources, reaffirming the industry's commitment to quality and reliability. For professionals entrenched in the oil and gas sector, these charts encapsulate a world of pivotal information, their trusted authority reinforcing decisions that shape the energy landscapes of tomorrow.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products