- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

tubing products

Understanding Tubing Products Applications, Materials, and Innovations

In the complex world of manufacturing and engineering, tubing products play a crucial role across various industries. From transporting fluids to providing structural support, these versatile components are essential in enhancing the efficiency and safety of numerous applications. This article aims to explore the different types of tubing products, the materials used in their production, and the innovations shaping their future.

What are Tubing Products?

Tubing products refer to hollow cylindrical components made from various materials, designed for a myriad of functions such as fluid transport, insulation, and structural application. They are widely utilized in industries like oil and gas, construction, automotive, and pharmaceuticals. Tubing comes in various diameters, lengths, and wall thicknesses, tailored to meet specific needs.

Types of Tubing Products

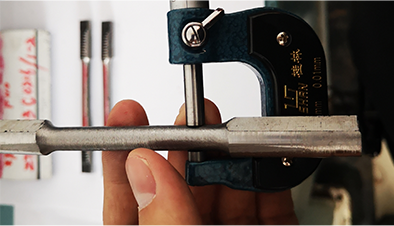

1. Metal Tubing Often made from materials like stainless steel, aluminum, or copper, metal tubing offers durability and strength. It's commonly used in industrial applications, plumbing, and aerospace industries due to its ability to withstand high pressure and temperature.

2. Plastic Tubing Materials such as PVC, polyethylene, and nylon are often used for plastic tubing. These products are lightweight, flexible, and resistant to corrosion, making them ideal for applications in medical devices, food processing, and irrigation systems.

3. Rubber Tubing Known for its flexibility and resilience, rubber tubing is used in automotive applications, fuel lines, and hydraulic systems. Its ability to absorb vibration and resist wear makes it a preferred choice in many demanding environments.

4. Glass Tubing This type of tubing product is often used in laboratories and scientific applications due to its non-reactive nature. Glass tubing is essential for creating various glassware and for applications where contamination must be minimized.

Key Applications

tubing products

Tubing products can be found in numerous applications

- Fluid Transport Tubing is extensively used for the transportation of gases and liquids in pipelines, ensuring efficient flow while minimizing leaks. - Automotive In vehicles, tubing is crucial for fuel lines, brake systems, and air conditioning, contributing to overall safety and performance.

- Medical Devices Tubing is vital in healthcare, used in equipment like IV lines, catheters, and diagnostic devices, where precision and reliability are paramount.

- Construction Structural tubing products are employed in scaffolding, supports, and other construction elements, ensuring stability and safety in buildings.

Material Innovations

The future of tubing products is being shaped by advancements in material science. Innovative materials such as composites, which combine the durability of metals with the lightweight characteristics of plastics, are gaining traction. These composites can provide enhanced performance in extreme conditions, making them suitable for aerospace and military applications.

Moreover, the rise of biocompatible materials is transforming the medical field. Tubing products made from these materials are increasingly being used in implants and other devices intended for long-term use in the human body.

Conclusion

Tubing products are integral to numerous industries, serving critical roles in fluid transport, structural support, and specialized applications. With ongoing innovations in materials and manufacturing processes, the future of tubing products holds promise for increased efficiency, safety, and versatility. As industries continue to evolve, the demand for high-quality tubing products will only grow, underscoring their importance in both existing applications and emerging technologies. Understanding the nuances of tubing products is essential for engineers and manufacturers striving for excellence in their respective fields.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025