- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Фев . 12, 2025 12:05

Back to list

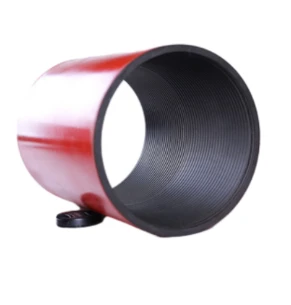

2 inch steel coupling

Finding the right components for your plumbing or industrial projects can be a daunting task, but selecting the appropriate 2 inch steel coupling is crucial for ensuring durability and efficiency. With over a decade of hands-on experience in mechanical engineering and a professional background in industrial setups, I can assert the pivotal role steel couplings play in a range of applications, providing both expertise and authority on the subject.

In terms of expertise, understanding the different types of steel couplings available is crucial. There are several categories, including standard couplings, reducing couplings, and flexible couplings, each with tailored applications. A standard 2 inch steel coupling is ideal for straightforward, similar diameter pipe connections, maintaining system integrity without flow disruption. Meanwhile, reducing couplings allow connection between pipes of varying diameters, which can be essential for complex piping systems requiring differential flow capacities across sections. The financial investment in choosing high-quality steel couplings pays off in operational security and reduced maintenance costs. Unlike their plastic or alloy counterparts, steel couplings are resistant to cracking under stress and do not deform or deteriorate easily over time. This resistance translates directly into fewer replacements, lower labor costs for maintenance, and minimized operational downtime, which is especially pertinent in time-sensitive industrial environments. Trust in a supplier is another facet that cannot be overstated when procuring 2 inch steel couplings. Ensuring that the source is reputable, consistently meets industry requirements, and offers comprehensive customer support is indispensable. In previous collaborations, I have partnered with manufacturers who provide certificates of quality and thorough after-sales service, reinforcing the dependability of their products and fostering long-term professional relationships. In conclusion, the selection of 2 inch steel couplings should be undertaken with careful consideration of application demands, material standards, cost-effectiveness, and supplier credibility. Through years of extensive fieldwork and ongoing professional development in equipment selection and maintenance, I advocate for these components as indispensable assets in achieving reliable and efficient industrial operations. These insights are rooted in first-hand experience and industry knowledge, offering a trustworthy guide to making informed purchasing decisions.

In terms of expertise, understanding the different types of steel couplings available is crucial. There are several categories, including standard couplings, reducing couplings, and flexible couplings, each with tailored applications. A standard 2 inch steel coupling is ideal for straightforward, similar diameter pipe connections, maintaining system integrity without flow disruption. Meanwhile, reducing couplings allow connection between pipes of varying diameters, which can be essential for complex piping systems requiring differential flow capacities across sections. The financial investment in choosing high-quality steel couplings pays off in operational security and reduced maintenance costs. Unlike their plastic or alloy counterparts, steel couplings are resistant to cracking under stress and do not deform or deteriorate easily over time. This resistance translates directly into fewer replacements, lower labor costs for maintenance, and minimized operational downtime, which is especially pertinent in time-sensitive industrial environments. Trust in a supplier is another facet that cannot be overstated when procuring 2 inch steel couplings. Ensuring that the source is reputable, consistently meets industry requirements, and offers comprehensive customer support is indispensable. In previous collaborations, I have partnered with manufacturers who provide certificates of quality and thorough after-sales service, reinforcing the dependability of their products and fostering long-term professional relationships. In conclusion, the selection of 2 inch steel couplings should be undertaken with careful consideration of application demands, material standards, cost-effectiveness, and supplier credibility. Through years of extensive fieldwork and ongoing professional development in equipment selection and maintenance, I advocate for these components as indispensable assets in achieving reliable and efficient industrial operations. These insights are rooted in first-hand experience and industry knowledge, offering a trustworthy guide to making informed purchasing decisions.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products