- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring Innovative Solutions in Tubing Products for Diverse Applications

Understanding Tubing Products An Essential Component in Various Industries

Tubing products play a crucial role in multiple sectors, ranging from oil and gas to pharmaceuticals, construction, and beyond. These products are designed to transport fluids, gases, and sometimes solids, making them indispensable in industrial applications. In this article, we will explore the various types of tubing products, their applications, material compositions, manufacturing processes, and future trends in this ever-evolving field.

Types of Tubing Products

Tubing products can be categorized based on their specific functions and materials. The primary types include

1. Steel Tubing Known for its durability and strength, steel tubing is widely used in the construction and automotive industries. It can withstand high pressure and harsh environments, making it perfect for carrying heavy loads of fluids and gases.

2. Plastic Tubing This type is lightweight and resistant to corrosion, making it suitable for applications where chemical exposure is a concern. Common materials for plastic tubing include PVC, polyethylene, and Teflon, often used in agriculture and food processing industries.

3. Copper Tubing Renowned for its thermal conductivity, copper tubing finds extensive applications in heating, cooling, and plumbing systems. Its resistance to corrosion also makes it ideal for transporting potable water.

4. Flexible Tubing Often made from various elastomers, flexible tubing can bend and shape easily, making it ideal for dynamic applications such as robotics and medical devices where rigidity isn't feasible.

5. Composite Tubing Combining materials, composite tubing is designed to optimize performance features, such as weight and strength. It finds extensive use in aerospace and automotive industries due to its high strength-to-weight ratio.

Applications and Industries

The versatility of tubing products means they cater to a wide array of industries. Here are some key applications

- Oil and Gas Tubing is crucial for drilling operations, transporting natural gas, oil, and various other fluids. Specialized steel tubes, for instance, are designed to withstand extreme conditions found in deep-sea oil exploration.

tubing products

- Medical In healthcare, tubing products are integral in delivering fluids to patients, such as IV lines. Medical-grade tubing must meet stringent FDA regulations, ensuring they do not leach harmful substances.

- Construction Rigid tubing is often used in the framework for plumbing and HVAC systems. Ensuring these systems are robust and leak-proof is crucial for building integrity and safety.

- Automotive Vehicles rely on tubing for multiple systems, including fuel lines, brake lines, and coolant circulation. High-strength materials are essential to withstand the rigors of daily use.

Manufacturing Processes

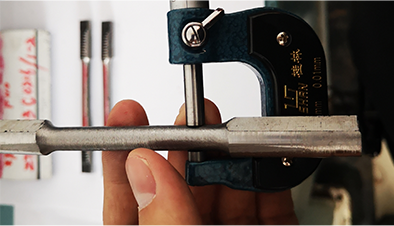

The production of tubing products involves several steps, including material selection, forming, welding, and finishing. Depending on the type of tubing, methods such as extrusion (for plastic tubing) or precision cutting and bending (for metal tubing) are employed. Manufacturers often utilize advanced technology, including CNC machining and laser cutting, to ensure the highest levels of precision and quality.

Future Trends

As industries evolve and technology advances, the future of tubing products appears promising. Here are some lasting trends

1. Sustainability With growing environmental concerns, manufacturers are increasingly turning to recyclable materials and production processes that minimize waste. Biodegradable plastics may emerge as alternatives for non-critical applications.

2. Smart Tubing The integration of IoT (Internet of Things) technologies into tubing products for real-time monitoring and diagnostics is on the rise. This innovation can enhance safety and efficiency, especially in industries such as oil and gas.

3. Customization As markets continue to demand specialized solutions, the ability to produce custom tubing products tailored to specific customer needs is becoming a competitive differentiator.

4. Advancements in Materials The development of new alloys and composites will enhance performance, offering benefits such as greater strength-to-weight ratios and better resistance to temperature changes and corrosive environments.

In conclusion, tubing products are vital components in a vast range of industries, providing crucial functionality in transporting gases and fluids. As technology continues to advance, so too will the designs, materials, and applications of tubing products, ensuring they remain an essential part of modern industrial and medical practices. Whether it’s through innovation in sustainability or smart technologies, the future of tubing is one of exciting possibilities.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025