- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Functionality and Applications of Steel Pipe Couplings in Construction Industry

Understanding Steel Pipe Couplings A Comprehensive Overview

Steel pipe couplings are critical components in the world of piping systems, playing an essential role in the transportation of fluids and gases across various applications. These fittings enable the connection of two or more lengths of pipe, ensuring a secure and leak-free operation. This article delves into the types, uses, and benefits of steel pipe couplings, providing a comprehensive understanding of their significance in industrial and construction settings.

Types of Steel Pipe Couplings

Steel pipe couplings come in various forms, each designed to serve specific purposes. The most common types include

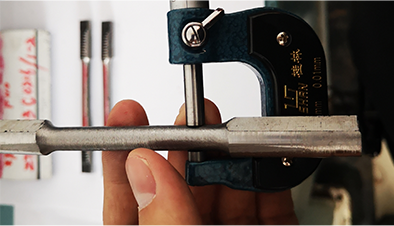

1. Screwed Couplings Also known as threaded couplings, these are used with pipes that have external threads. They can be quickly assembled and disassembled, making them a popular choice for temporary connections or maintenance tasks.

2. Welded Couplings These couplings are welded to the pipe ends, providing a permanent and robust connection. They are ideal for high-pressure applications where strength is critical.

3. Compression Couplings Designed to connect pipes without the need for welding or threading, compression couplings use a mechanical grip to ensure a tight seal. They are particularly useful in plumbing applications.

4. Flanged Couplings These consist of two flanges that are bolted together, allowing for easy disassembly when maintenance is required. Flanged couplings are commonly used in large diameter pipes and high-pressure systems.

5. Dissolvable Couplings A newer innovation, these couplings are designed to dissolve in specific chemical environments, making them useful in industries where temporary connections are needed without leaving physical remnants.

Applications of Steel Pipe Couplings

Steel pipe couplings are prevalent in numerous industries, including oil and gas, water treatment, construction, and manufacturing. Their primary applications include

steel pipe coupling

- Transporting Fluids and Gases Couplings provide the necessary connections in pipelines for transporting hazardous and non-hazardous materials efficiently.

- Infrastructure Development In construction, steel pipe couplings are integral to creating reliable plumbing systems, HVAC installations, and fire fighting systems

.- Maintenance and Repair When pipelines need to be repaired or modified, couplings allow for quick and effective solutions without the need for extensive replacements.

Benefits of Steel Pipe Couplings

The advantages of using steel pipe couplings are numerous

- Strength and Durability Steel is known for its high tensile strength, ensuring that couplings can withstand high pressures and harsh environmental conditions.

- Versatility With various types available, steel couplings can be used in diverse applications, adapting to the specific needs of each project.

- Easy Installation and Maintenance Many steel pipe couplings can be installed without specialized tools, reducing labor time and costs. Additionally, their design facilitates easy maintenance.

- Cost-Effective Investing in quality steel couplings can lead to significant savings in terms of operational costs and maintenance over time, especially in large-scale applications.

Conclusion

In summary, steel pipe couplings are indispensable components in modern piping systems, offering strength, versatility, and ease of use. Their role in connecting pipes ensures seamless fluid and gas transportation across various industries, making them a preferred choice for engineers and construction professionals alike. Understanding the different types and applications of steel pipe couplings can aid in selecting the appropriate solution for any project, ultimately contributing to the efficiency and safety of piping systems. As industries continue to evolve, the importance of reliable couplings in maintaining functionality in infrastructural projects will only increase.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025