- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Јан . 26, 2025 00:36

Back to list

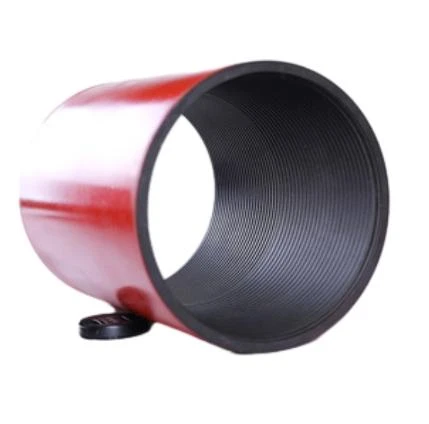

Tubing Coupling

Understanding the nuances of various industrial components is essential for professionals in fields such as oil and gas, plumbing, and engineering. One often overlooked yet critical piece of equipment is the bull plug. Despite its mundane appearance, the bull plug plays a crucial role in ensuring the integrity and functionality of pipeline systems.

Anecdotal experiences from industry veterans underscore the importance of routine maintenance checks. Over time, the materials of even the most resilient bull plugs can degrade. Visual inspections for signs of corrosion, distortion, or other forms of wear and tear should be part of any regular maintenance schedule. Some operators also employ ultrasonic testing to detect invisible internal flaws that could compromise the plug's integrity. The installation of a bull plug is another area where expertise shines. Proper installation not only ensures that the plug functions correctly but also extends the overall lifespan of the system. Using the correct tools, such as a pipe wrench or torque wrench depending on the threading requirements, and adhering to the manufacturer's specifications for torque levels are critical. An under-tightened plug might lead to leaks, while over-tightening can strip the threads, both of which are undesirable. For industries where safety is paramount, particularly those dealing with volatile substances, the reliability of bull plugs cannot be overstated. Ensuring that these small but mighty devices are correctly installed and maintained forms the backbone of a dependable pipeline system. Professional training sessions and certification programs are recommended for technicians involved in work with bull plugs to further instil best practices. In summary, while a bull plug may seem like a simple, unassuming component within a vast network of pipelines, its role is indispensable. Through careful selection, diligent maintenance, and correct installation, bull plugs contribute markedly to the safety and efficiency of industrial operations. By understanding their functions and implementing them with integrity, industries can bolster their reliability while minimizing both risk and downtime.

Anecdotal experiences from industry veterans underscore the importance of routine maintenance checks. Over time, the materials of even the most resilient bull plugs can degrade. Visual inspections for signs of corrosion, distortion, or other forms of wear and tear should be part of any regular maintenance schedule. Some operators also employ ultrasonic testing to detect invisible internal flaws that could compromise the plug's integrity. The installation of a bull plug is another area where expertise shines. Proper installation not only ensures that the plug functions correctly but also extends the overall lifespan of the system. Using the correct tools, such as a pipe wrench or torque wrench depending on the threading requirements, and adhering to the manufacturer's specifications for torque levels are critical. An under-tightened plug might lead to leaks, while over-tightening can strip the threads, both of which are undesirable. For industries where safety is paramount, particularly those dealing with volatile substances, the reliability of bull plugs cannot be overstated. Ensuring that these small but mighty devices are correctly installed and maintained forms the backbone of a dependable pipeline system. Professional training sessions and certification programs are recommended for technicians involved in work with bull plugs to further instil best practices. In summary, while a bull plug may seem like a simple, unassuming component within a vast network of pipelines, its role is indispensable. Through careful selection, diligent maintenance, and correct installation, bull plugs contribute markedly to the safety and efficiency of industrial operations. By understanding their functions and implementing them with integrity, industries can bolster their reliability while minimizing both risk and downtime.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products