- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1-р сар . 25, 2025 22:11

Back to list

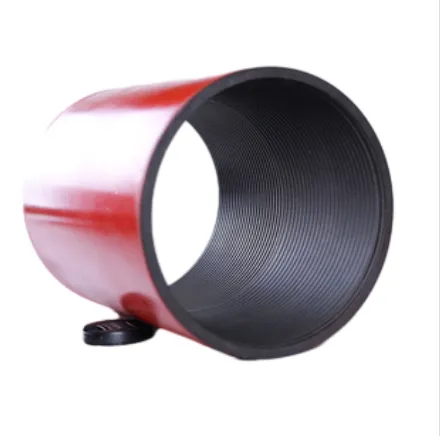

pup joint oil and gas

In the ever-evolving world of oil and gas exploration, the use of advanced equipment and components is paramount to optimizing production and ensuring safety. Among the myriad tools leveraged by petroleum engineers, the bull plug plays a discreet yet critical role in the functioning of various operations within the sector. This article delves into the specifics of bull plugs, shedding light on their significance, applications, and the expertise required to employ them effectively.

In addition to technical expertise, a noteworthy aspect of the bull plug's application is the adherence to industry standards and regulatory requirements. The oil and gas industry is governed by strict regulations aimed at safeguarding the environment and ensuring the safety of personnel. As such, the use of bull plugs must comply with these standards, necessitating that companies procure their equipment from reputable suppliers who uphold stringent quality control measures. As the industry advances, innovations in bull plug design and materials continue to enhance their performance. Engineers and manufacturers are exploring the use of advanced alloys and coatings that offer superior resistance to corrosion and wear, thereby extending the lifespan of the equipment and reducing the frequency of replacements. These advancements not only contribute to operational efficiency but also align with the industry's push towards sustainable and cost-effective practices. Trustworthiness in the use of bull plugs can be achieved by sourcing them from reputable manufacturers renowned for their commitment to quality and innovation. Additionally, fostering relationships with industry experts and institutions that specialize in oil and gas exploration can provide invaluable insights into best practices and emerging technologies. In conclusion, bull plugs, while small and often overlooked, are pivotal in the smooth and safe operation of oil and gas exploration and production processes. Their proper selection, installation, and maintenance require a blend of experience, expertise, and adherence to industry standards. As technological advancements continue to shape the sector, the role of bull plugs will undoubtedly evolve, offering new opportunities to enhance efficiency and safety in oil and gas operations globally. Companies committed to leveraging these components stand to gain significantly, securing their place in an increasingly competitive industry.

In addition to technical expertise, a noteworthy aspect of the bull plug's application is the adherence to industry standards and regulatory requirements. The oil and gas industry is governed by strict regulations aimed at safeguarding the environment and ensuring the safety of personnel. As such, the use of bull plugs must comply with these standards, necessitating that companies procure their equipment from reputable suppliers who uphold stringent quality control measures. As the industry advances, innovations in bull plug design and materials continue to enhance their performance. Engineers and manufacturers are exploring the use of advanced alloys and coatings that offer superior resistance to corrosion and wear, thereby extending the lifespan of the equipment and reducing the frequency of replacements. These advancements not only contribute to operational efficiency but also align with the industry's push towards sustainable and cost-effective practices. Trustworthiness in the use of bull plugs can be achieved by sourcing them from reputable manufacturers renowned for their commitment to quality and innovation. Additionally, fostering relationships with industry experts and institutions that specialize in oil and gas exploration can provide invaluable insights into best practices and emerging technologies. In conclusion, bull plugs, while small and often overlooked, are pivotal in the smooth and safe operation of oil and gas exploration and production processes. Their proper selection, installation, and maintenance require a blend of experience, expertise, and adherence to industry standards. As technological advancements continue to shape the sector, the role of bull plugs will undoubtedly evolve, offering new opportunities to enhance efficiency and safety in oil and gas operations globally. Companies committed to leveraging these components stand to gain significantly, securing their place in an increasingly competitive industry.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products