- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

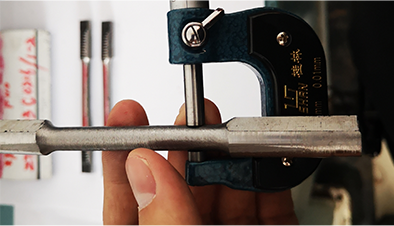

stainless steel hose couplings

Understanding Stainless Steel Hose Couplings A Comprehensive Guide

Stainless steel hose couplings are essential components in a variety of industrial and commercial applications. Known for their durability, resistance to corrosion, and ability to withstand high temperatures, stainless steel couplings provide reliable connections in various environments, from manufacturing plants to food processing facilities.

What are Stainless Steel Hose Couplings?

Stainless steel hose couplings are devices that connect different lengths of hoses for transporting fluids, gases, or other materials. They are typically made from high-grade stainless steel, which is an alloy that includes chromium and nickel, providing resistance to rust and corrosion. This material is particularly suited for applications that involve harsh chemicals or extreme temperatures.

Types of Stainless Steel Hose Couplings

There are several types of stainless steel hose couplings, each designed for specific applications

1. Camlock Couplings These are quick-connect couplings that allow for easy and efficient connection and disconnection of hoses. They are widely used in agriculture, water treatment, and chemical processing.

2. Threaded Couplings These couplings feature male and female threaded ends, ensuring a secure connection. They are commonly found in plumbing and gas applications.

3. Hygienic Couplings Designed for food and pharmaceutical industries, these couplings maintain high hygiene standards. They are easy to clean and provide a secure fit to prevent contamination.

4. Flange Couplings These couplings feature flanges that bolt together, offering a strong connection for high-pressure applications. They are often used in oil and gas industries.

stainless steel hose couplings

Advantages of Stainless Steel Hose Couplings

The benefits of using stainless steel hose couplings are numerous

- Corrosion Resistance Stainless steel's natural resistance to oxidation means that these couplings can withstand exposure to humidity, chemicals, and other corrosive substances without degrading.

- Durability Designed to endure mechanical stresses, stainless steel couplings have a long lifespan, reducing the need for frequent replacements.

- High-Temperature Tolerance Stainless steel can maintain its structural integrity even in high-temperature environments, making it ideal for steam applications and hot liquid transport.

- Versatility Suitable for a wide range of industries, including automotive, food and beverage, pharmaceuticals, and chemical processing, stainless steel hose couplings are adaptable to various needs.

Installation and Maintenance

To ensure optimal performance and longevity, proper installation and maintenance of stainless steel hose couplings are essential. This includes selecting the right type of coupling for the specific application, ensuring that the hoses are compatible, and regularly inspecting the couplings for wear or damage. Tightening connections according to manufacturer specifications can prevent leaks and failures.

Conclusion

Stainless steel hose couplings play a critical role in numerous applications where reliability and safety are paramount. Their resistance to corrosion, durability, and versatility make them an ideal choice for industries that require the transfer of fluids and gases under various conditions. Understanding the various types and applications of these couplings can help businesses make informed decisions, ensuring efficiency and reliability in their operations. Investing in quality stainless steel hose couplings is a step toward achieving optimal performance and longevity in any operational setting.

-

Understanding Tubing Crossover: Tools for Enhanced Oilfield OperationsNewsAug.08,2025

-

Tubing Pup Joint: The Ideal Choice for Oil and Gas OperationsNewsAug.08,2025

-

Tubing and Casing: Essential Components in Oil and Gas ProductionNewsAug.08,2025

-

Introduction to Tubing CouplingNewsAug.08,2025

-

Casing Pup Joint: The Essential Component for Oil and Gas OperationsNewsAug.08,2025

-

Casing Coupling: The Essential Link in Well ConstructionNewsAug.08,2025