- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Casing Coupling Specifications and Dimensional Standards for Oil and Gas Industry Applications

Understanding Casing Coupling Dimensions in Oil and Gas Industry

In the oil and gas industry, the efficiency of drilling operations heavily relies on various components, one of which is the casing coupling. Casings and their couplings play a significant role in ensuring the integrity and success of well construction. This article explores the essential aspects of casing coupling dimensions, their importance, and the standards governing them.

What is Casing and Coupling?

Casing is a series of steel pipes that are inserted into a drilled well to stabilize the wellbore and prevent contamination of groundwater. Couplings, on the other hand, are fittings designed to connect two sections of casing. Proper selection and specification of casing and coupling dimensions are crucial for the structural integrity of the well, as they must withstand high pressures, temperatures, and corrosive environments typically found in oil and gas extraction operations.

Importance of Accurate Dimensions

The dimensions of casing and coupling significantly influence the overall performance of the well. Key parameters include the outer diameter (OD), inner diameter (ID), wall thickness, and thread specifications. If the dimensions are not accurately adhered to, several issues can arise

1. Structural Integrity Inadequate dimensions can compromise the structural integrity of the well, leading to potential failures and safety hazards. 2. Pressure Resistance The casing must withstand high internal and external pressures. Incorrect dimensions can diminish the casing's ability to handle these stresses, resulting in potential leaks or collapses.

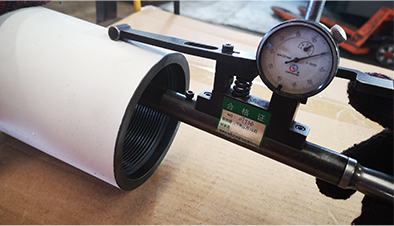

casing coupling dimensions

3. Corrosion Resistance The appropriate wall thickness helps to mitigate corrosion. A casing with insufficient thickness may corrode faster, leading to premature failure.

4. Compatibility Couplings must match the casing's dimensions precisely to ensure a secure and leak-free connection. Mismatched dimensions can lead to connection failures during the drilling process.

Industry Standards

To ensure the reliability and safety of casing and couplings, various industry standards are in place. The American Petroleum Institute (API) is one of the leading organizations establishing these standards. The API specifications outline the acceptable dimensions, tolerances, and material properties necessary for casing and coupling components used in oil and gas wells.

These standards dictate the dimensions based on several factors, including the intended use of the well, the geological environment, and the specific requirements of the drilling operation. Adherence to these standards not only facilitates interoperability between components from different manufacturers but also ensures safety across the board.

Conclusion

In summary, the dimensions of casing and coupling are critical to the success of oil and gas drilling operations. Accurate specifications ensure structural integrity, pressure resistance, and compatibility, all which are vital to the safety and efficiency of drilling activities. Adopting established industry standards, such as those from the API, plays a fundamental role in achieving these objectives. As the energy sector continues to evolve with advancements in technology and increased complexity in extraction methods, the significance of precise casing coupling dimensions will only grow, making it a key focus area for engineers and drilling professionals alike. Understanding and implementing proper casing coupling dimensions will ultimately contribute to safer and more efficient oil and gas operations, paving the way for future developments in the industry.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025