- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Benefits and Applications of Steel Couplings in Modern Engineering Solutions

Understanding Steel Couplings A Key Component in Mechanical Engineering

Steel couplings play an essential role in mechanical engineering, particularly in the fabrication of machinery. They serve as connectors between two rotating shafts, allowing them to transmit torque while accommodating for misalignment, vibration, and axial movement. The significance of steel couplings cannot be understated, as they are a critical component in various applications, from manufacturing equipment to automotive and aerospace systems.

What are Steel Couplings?

A coupling is defined as a mechanical device used to connect two shafts together at their ends for the purpose of transmitting power. Steel couplings are specifically made from high-strength steel, which offers excellent durability and resistance to wear and tear. These couplings come in various designs, including rigid, flexible, and adjustable types, each serving a unique purpose and offering specific advantages based on the requirements of the application.

Types of Steel Couplings

1. Rigid Couplings These couplings provide a solid connection between two shafts without any flexibility. They are often used in applications where precise alignment is crucial, and the shafts do not experience misalignment. Rigid couplings are commonly found in power plants, conveyor systems, and other industrial machinery.

2. Flexible Couplings Unlike rigid couplings, flexible couplings allow for some degree of misalignment between the shafts. This flexibility is crucial in applications where vibrations or shifts can occur. Flexible couplings come in various designs, including nylon, rubber, and metallic configurations, each providing the necessary flexibility to absorb shock and vibrations.

3. Adjustable Couplings These couplings allow for adjustments in length, making them suitable for applications where the distance between shafts may vary. Adjustable couplings are commonly used in industries where equipment may need to be repositioned frequently, such as in modular machinery setups.

Applications of Steel Couplings

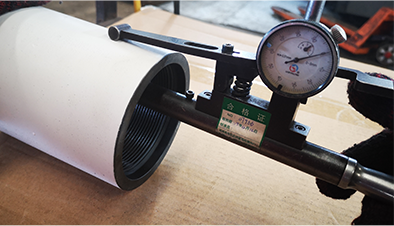

steel coupling

Steel couplings can be found across various industries, serving pivotal roles in diverse applications.

- Manufacturing In the manufacturing sector, steel couplings are integral components in conveyor systems, assembly lines, and machine tools

. They ensure seamless power transmission while accommodating any slight misalignments that may arise from heavy loads or operational wear.- Automotive In the automotive industry, steel couplings are used in drive shafts, gearboxes, and engine systems. Their robust nature enables them to handle high levels of torque and stress, enhancing vehicle performance and reliability.

- Aerospace The aerospace sector demands high-performance components that can withstand extreme conditions. Steel couplings are employed in various aircraft systems, from propulsion to hydraulic systems. Their resistance to fatigue and ability to maintain performance under stress make them invaluable in this high-stakes industry.

Advantages of Steel Couplings

The choice of steel for couplings comes with several advantages. Firstly, steel offers superior strength and durability compared to other materials, ensuring that couplings can handle high loads and operate effectively in demanding environments. Secondly, steel couplings exhibit excellent resilience against temperature fluctuations and corrosion, particularly when treated with protective coatings. This resistance leads to a longer lifespan and reduces maintenance costs.

Furthermore, steel couplings can be manufactured in numerous sizes and configurations, allowing for customization to meet specific application needs. This versatility is a significant advantage for engineers looking to optimize their designs for performance and efficiency.

Conclusion

In summary, steel couplings are vital components in mechanical systems, facilitating effective power transmission and ensuring the smooth operation of machinery across various industries. Their diverse types and advantages make them suitable for a wide range of applications, from manufacturing to aerospace. As technology continues to advance, the importance of reliable and efficient couplings, particularly those made of steel, will only increase in the quest for enhanced machinery performance. For engineers and manufacturers alike, understanding the role and benefits of steel couplings is crucial in driving innovation and efficiency in mechanical design and production.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025