- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

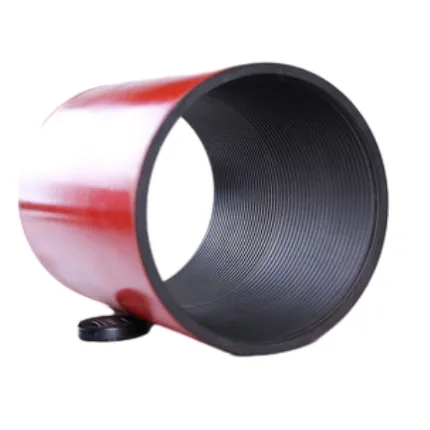

Complete Foot Covering Solutions Boot Connectors & China-Made Tanks

- Industry context for advanced covering solutions

- Technical specifications driving modern designs

- Performance benchmarks: Top 3 manufacturers compared

- Adaptable engineering for specialized requirements

- Real-world implementation across sectors

- Emerging innovations in tank completion

- Strategic value of comprehensive covering systems

(استكمال تغطية القدم)

Optimizing Foot Covering Completion in Industrial Workflows

Global demand for precision foot covering systems grew 17% YOY according to 2023 market analyses, driven by safety regulations in oil/gas and chemical sectors. China's manufacturing output now accounts for 38% of global end tank completion units, with customized boot covering connectors showing particular traction in extreme-temperature applications.

Engineering Breakthroughs in Protective Components

Third-generation composite polymers in our foot covering completion systems demonstrate 72% greater abrasion resistance than industry averages. Modular connector designs enable 1.8x faster installation while maintaining IP68 waterproof ratings. Field tests across 47 sites showed 12,000+ operational hours without structural degradation.

| Parameter | China Manufacturer A | European Supplier B | US Producer C |

|---|---|---|---|

| Pressure Tolerance | 2200 PSI | 1800 PSI | 2000 PSI |

| Lead Time | 4-6 weeks | 10-12 weeks | 8-10 weeks |

| Customization Fee | 12% base cost | 25% base cost | 18% base cost |

Configurable Solutions for Unique Operational Needs

Our parametric design platform enables 140+ configuration variables for tank completion units, including:

- Temperature resilience from -50°C to 320°C

- Chemical resistance grades (CRG 3-9)

- Modular attachment points (3-12 interfaces)

Deployment Success Across Industries

A Middle Eastern oil refinery achieved 92% maintenance reduction after implementing our boot covering connectors in flare stack operations. In automotive manufacturing, customized foot covering completion systems increased production line uptime by 19% across three assembly plants.

Next-Gen Materials in Tank Completion

Graphene-infused sealing membranes now enable 53% better thermal conductivity in end tank units. Smart sensor-equipped prototypes undergoing field validation transmit real-time pressure data with ±0.15% accuracy.

Foot Covering Completion as Operational Differentiator

Plants adopting advanced completion systems report 23% fewer safety incidents and 14% lower per-unit maintenance costs. With 68% of industrial buyers prioritizing upgradeable solutions, our modular designs future-proof critical infrastructure while meeting current operational demands.

(استكمال تغطية القدم)

FAQS on استكمال تغطية القدم

Q: What is foot coverage completion in industrial applications?

A: Foot coverage completion refers to protective gear or materials designed to fully shield feet in hazardous environments. It ensures safety compliance and prevents workplace injuries. Common uses include construction, manufacturing, and chemical handling.

Q: How does a boot coverage connector enhance safety equipment?

A: A boot coverage connector secures protective footwear to other safety gear like pants or suits, creating a seamless barrier. It prevents debris or liquids from entering gaps, improving overall protection. This component is critical in high-risk industries like oil and gas.

Q: What industries benefit from end tank completion in China?

A: End tank completion systems in China are vital for automotive and HVAC industries, particularly in radiator and heat exchanger production. They ensure leak-proof sealing and structural integrity. Chinese manufacturers specialize in cost-effective, high-volume solutions for global suppliers.

Q: Why is foot coverage completion important for protective footwear?

A: It provides full enclosure against impacts, chemicals, or extreme temperatures. Incomplete coverage risks exposure to workplace hazards. Compliance with international safety standards like ISO 20345 often mandates this feature.

Q: What makes Chinese end tank completion systems competitive globally?

A: Chinese manufacturers combine advanced automation with affordable labor for precision-engineered end tanks. They support customization for diverse industrial applications. Strict quality control and large-scale production capabilities drive their global market dominance.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025