Feb . 20, 2025 10:15

Back to list

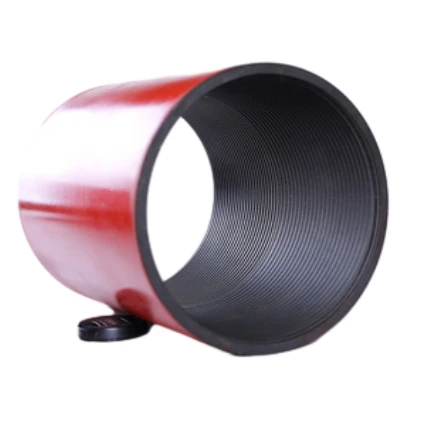

what is a bull plug used for

The bull plug is an indispensable tool in the field of oil and gas extraction and mechanical engineering. Traditionally, it is a cylindrical device used to close off the end of a pipe. Its versatile applications and robust design make it a staple in both industries, ensuring operational safety and efficiency.

Real-world experiences emphasize the necessity of incorporating bull plugs within a risk management framework. For instance, oil field operators recount scenarios where the use of bull plugs prevented environmental contamination due to unexpected pressure build-ups. Proper deployment of bull plugs underlines adherence to environmental regulations and ethical standards, fostering trust with stakeholders and the public. Furthermore, purchasing bull plugs from authoritative suppliers and verified manufacturers guarantees a higher level of trust and reliability. These suppliers not only provide products that meet rigorous industry specifications but also offer expert guidance on installation and maintenance best practices. This holistic approach to procurement reassures companies that their operations rest on a foundation of quality and safety. In conclusion, the bull plug represents a convergence of practical utility and expertise within industrial domains. Its role in maintaining operational integrity, coupled with its importance in safety protocols, highlights why it remains a critical component. Crafting a strategy around the effective use of bull plugs, from knowledgeable sourcing to adept installation, embodies a commitment to operational excellence and environmental stewardship. Such an approach not only safeguards physical assets but also reinforces the trust and authority that industry leaders seek to maintain.

Real-world experiences emphasize the necessity of incorporating bull plugs within a risk management framework. For instance, oil field operators recount scenarios where the use of bull plugs prevented environmental contamination due to unexpected pressure build-ups. Proper deployment of bull plugs underlines adherence to environmental regulations and ethical standards, fostering trust with stakeholders and the public. Furthermore, purchasing bull plugs from authoritative suppliers and verified manufacturers guarantees a higher level of trust and reliability. These suppliers not only provide products that meet rigorous industry specifications but also offer expert guidance on installation and maintenance best practices. This holistic approach to procurement reassures companies that their operations rest on a foundation of quality and safety. In conclusion, the bull plug represents a convergence of practical utility and expertise within industrial domains. Its role in maintaining operational integrity, coupled with its importance in safety protocols, highlights why it remains a critical component. Crafting a strategy around the effective use of bull plugs, from knowledgeable sourcing to adept installation, embodies a commitment to operational excellence and environmental stewardship. Such an approach not only safeguards physical assets but also reinforces the trust and authority that industry leaders seek to maintain.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products