- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Chingerezi

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

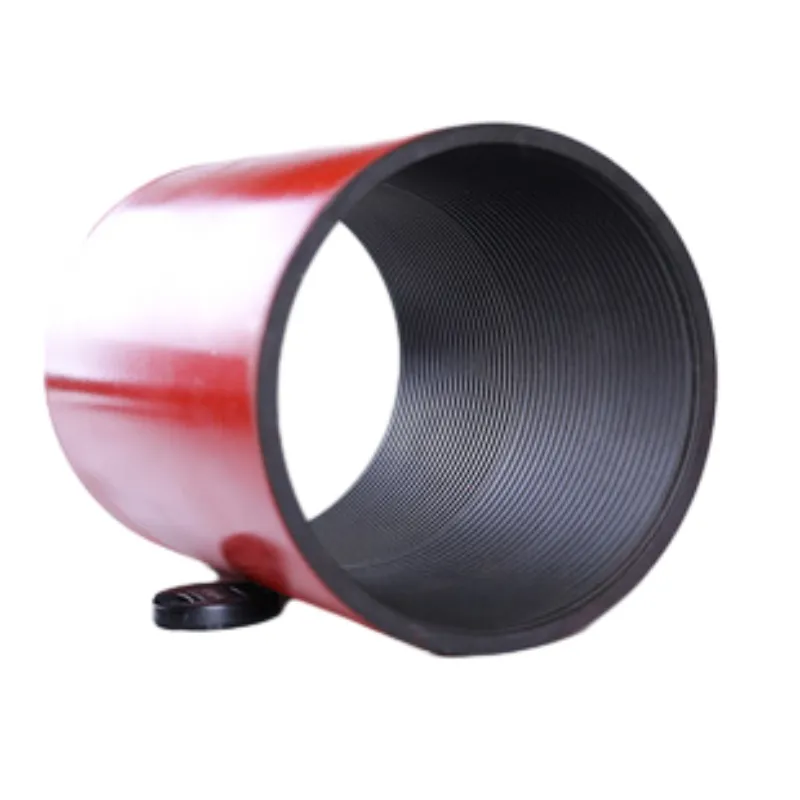

Well Casing Extension Couplings – Applications and Installation

When it comes to oilfield and drilling operations, well casing extension couplings play a crucial role in ensuring structural integrity and seamless connections. These components are essential for joining API casing sections, accommodating different API casing sizes, and reinforcing the overall well structure. Whether used in wholesale API threading or as part of a coupling casing system, these extensions provide durability and reliability in demanding environments.

This article explores the applications and installation of well casing extension couplings, highlighting their importance in drilling operations.

Understanding Well Casing Extension Couplings

Well casing extension couplings are specialized connectors designed to join two sections of API casing when standard lengths are insufficient. These couplings are manufactured to meet stringent API threading standards, ensuring compatibility with various API casing sizes. They are commonly used in drilling operations where extended well depths require additional casing support These couplings are engineered for durability and reliability, capable of withstanding the extreme pressures and temperatures encountered in deep-well environments. Their precision threading ensures a secure and leak-proof connection, critical for maintaining well integrity and preventing costly downtime. Additionally, well casing extension couplings are often made from high-strength materials to resist corrosion and wear, enhancing their lifespan and performance in harsh subterranean conditions..

Constructed from high-grade steel, these coupling casing components resist corrosion and withstand high pressure, making them ideal for harsh well conditions.

Furthermore, their robust construction ensures that they can be reused multiple times, contributing to cost savings and sustainability in drilling operations. This reusability factor is particularly advantageous in the oil and gas industry, where minimizing expenses and maximizing efficiency are paramount.

Applications of Casing Extension Couplings

The primary use of well casing extension couplings is to bridge gaps between casing strings, ensuring a continuous and secure well structure. Key applications include:

Extending well depth – When drilling deeper than standard casing lengths, these couplings allow for seamless extensions.

Repairing damaged casing – They can replace compromised sections without requiring a full casing replacement.

Adapting to non-standard well designs – Some wells require custom API casing sizes, and extension couplings provide the necessary flexibility.

These couplings are widely used in wholesale API threading projects, where bulk orders are needed for large-scale drilling operations.

In addition, they offer several practical advantages such as:

Cost-effectiveness – Extension couplings often cost less than full casing replacements, making them a more budget-friendly option for well maintenance and upgrades.

Ease of installation – Designed for quick and easy assembly, these couplings minimize downtime and speed up drilling processes.

Versatility in material compatibility – Available in various materials, including steel and alloy, they can accommodate different well conditions and drilling fluid compositions.

Durability and reliability – Manufactured to stringent industry standards, extension couplings ensure long-term performance and withstand the harsh environments typical of oil and gas exploration.

Installation of Well Casing Extension Couplings

Proper installation of coupling casing components is critical for well integrity. The process involves:

Preparing the casing ends – Ensure clean, undamaged threads for a secure fit.

Applying thread compound – Prevents leaks and enhances connection strength.

Tightening to API specifications – Proper torque ensures a pressure-tight seal.

Installation must follow API threading guidelines to avoid failures that could compromise the well.

Choosing the Right API Casing Sizes

Selecting the correct API casing sizes is essential for optimal performance. Factors to consider include:

Well diameter and depth – Determines the required casing thickness and length.

Pressure and temperature conditions – Influences material selection.

Compatibility with existing casing – Ensures seamless integration.

Consulting wholesale API threading suppliers can help identify the best coupling casing solutions for specific projects.

FAQ – Common Questions About Well Casing Extension Couplings

What materials are used in well casing extension couplings?

Most couplings are made from high-strength carbon or alloy steel, treated for corrosion resistance and durability.

How do I ensure proper threading compatibility?

Always verify that the API threading matches the API casing sizes being used to prevent connection failures.

Can extension couplings be reused?

While possible, reusing couplings is not recommended due to potential thread wear and reduced sealing efficiency.

What are the signs of a faulty casing coupling?

Leaks, uneven pressure distribution, and visible thread damage indicate a failing coupling casing.

Where can I buy wholesale API threading couplings?

Reputable oilfield equipment suppliers and manufacturers offer wholesale API threading products in various API casing sizes.

By understanding the role and installation of well casing extension couplings, drilling professionals can enhance well integrity and operational efficiency. Whether used for extending depth or repairing casings, these components are indispensable in modern drilling operations.

However, the question arises whether these extension couplings can be reused. Generally, the reusability of extension couplings depends on their condition after the initial use. If they have not sustained any damage and are still in good working condition, they can often be reused. It is crucial to inspect the couplings thoroughly before reuse to ensure they meet the required safety and performance standards. Reusing extension couplings can help reduce costs and waste, provided they are still fit for purpose.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNkhaniNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNkhaniNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNkhaniNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNkhaniNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNkhaniNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNkhaniNov.03,2025