- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 18, 2024 01:57

Back to list

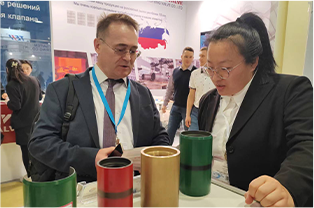

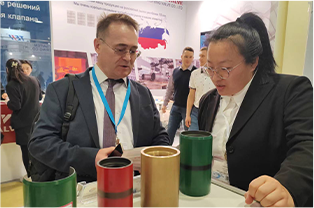

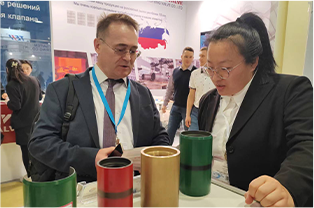

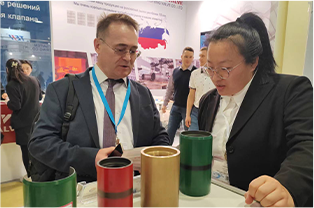

Coupling tube fittings for efficient piping.

The Versatility of Coupling Tube Fittings in Plumbing and Industrial Applications

In the vast expanse of engineering marvels, coupling tube fittings emerge as unsung heroes, silently ensuring the seamless transition of fluids from one pipe to another. These fittings, often overlooked, play a pivotal role in plumbing systems and industrial applications, where their reliability and efficiency are paramount.

Coupling tube fittings, also known as unions or union fittings, consist of two halves that separate to allow for easy installation and removal of pipes without leaking or spilling the contents within. This design feature is particularly beneficial during maintenance or repairs, saving time and reducing potential downtime significantly. The ability to disassemble these fittings without disturbing the system's integrity is a testament to their clever construction.

The materials used in the creation of coupling tube fittings range from brass and bronze to stainless steel and even plastic, each tailored to handle different types of fluids under various pressures and temperatures. For instance, brass fittings are common in water supply systems due to their excellent resistance to corrosion and durability. Stainless steel variants, on the other hand, are favored in high-pressure environments or when conveying hazardous chemicals because of their superior strength and chemical resistance.

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks coupling tube fitting. These threads can be standard or can follow specific patterns such as NPT (National Pipe Thread), BSP (British Standard Pipe), or other international standards, ensuring compatibility across different projects and countries.

In industrial settings, coupling tube fittings are indispensable for processes involving steam, gas, or other industrial fluids. They provide a controlled environment for pressure regulation and offer an accessible solution for periodic checks and cleaning routines. The ease of installation and removal makes them ideal for situations requiring frequent maintenance or part replacement.

The simplicity of coupling tube fittings belies their importance. They are not merely connectors; they are safeguards against leakage, enablers of efficient maintenance, and essential components in the smooth operation of both residential and industrial piping systems. As we navigate through the labyrinthine networks of pipelines that sustain our daily lives and industrial output, the humble coupling tube fitting continues to quietly perform its vital function, ensuring the steady flow of resources that drive modern civilization.

coupling tube fitting. These threads can be standard or can follow specific patterns such as NPT (National Pipe Thread), BSP (British Standard Pipe), or other international standards, ensuring compatibility across different projects and countries.

In industrial settings, coupling tube fittings are indispensable for processes involving steam, gas, or other industrial fluids. They provide a controlled environment for pressure regulation and offer an accessible solution for periodic checks and cleaning routines. The ease of installation and removal makes them ideal for situations requiring frequent maintenance or part replacement.

The simplicity of coupling tube fittings belies their importance. They are not merely connectors; they are safeguards against leakage, enablers of efficient maintenance, and essential components in the smooth operation of both residential and industrial piping systems. As we navigate through the labyrinthine networks of pipelines that sustain our daily lives and industrial output, the humble coupling tube fitting continues to quietly perform its vital function, ensuring the steady flow of resources that drive modern civilization.

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks

The threaded ends of coupling tube fittings ensure a secure connection with corresponding threads on the pipes, further preventing leaks coupling tube fitting. These threads can be standard or can follow specific patterns such as NPT (National Pipe Thread), BSP (British Standard Pipe), or other international standards, ensuring compatibility across different projects and countries.

In industrial settings, coupling tube fittings are indispensable for processes involving steam, gas, or other industrial fluids. They provide a controlled environment for pressure regulation and offer an accessible solution for periodic checks and cleaning routines. The ease of installation and removal makes them ideal for situations requiring frequent maintenance or part replacement.

The simplicity of coupling tube fittings belies their importance. They are not merely connectors; they are safeguards against leakage, enablers of efficient maintenance, and essential components in the smooth operation of both residential and industrial piping systems. As we navigate through the labyrinthine networks of pipelines that sustain our daily lives and industrial output, the humble coupling tube fitting continues to quietly perform its vital function, ensuring the steady flow of resources that drive modern civilization.

coupling tube fitting. These threads can be standard or can follow specific patterns such as NPT (National Pipe Thread), BSP (British Standard Pipe), or other international standards, ensuring compatibility across different projects and countries.

In industrial settings, coupling tube fittings are indispensable for processes involving steam, gas, or other industrial fluids. They provide a controlled environment for pressure regulation and offer an accessible solution for periodic checks and cleaning routines. The ease of installation and removal makes them ideal for situations requiring frequent maintenance or part replacement.

The simplicity of coupling tube fittings belies their importance. They are not merely connectors; they are safeguards against leakage, enablers of efficient maintenance, and essential components in the smooth operation of both residential and industrial piping systems. As we navigate through the labyrinthine networks of pipelines that sustain our daily lives and industrial output, the humble coupling tube fitting continues to quietly perform its vital function, ensuring the steady flow of resources that drive modern civilization. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products