- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 10, 2025 10:12

Back to list

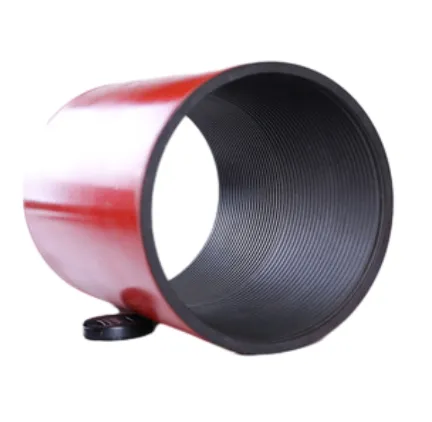

casing coupling china manufacturer

The J55 coupling is an integral part of the oil and gas industry, representing a vital connection fitting in a broader system crucial for efficient operations. Engineers and technicians alike often cite this model as a linchpin in ensuring safety, particularly in high-stress environments. With its robust composition and design, the J55 coupling allows for substantial pressure containment and efficient fluid transport, marking it as indispensable for industry professionals.

Field experience showcases the J55 coupling’s practical application and efficiency in real-world scenarios. For example, operators have noted significant decreases in maintenance costs and incidents of equipment failure when employing this coupling. Real-world applications affirm its engineered qualities, demonstrating a proven record of reliable service throughout rigorous cycles. The coupling's durability, particularly in high-output environments, provides concrete evidence of its craftsmanship—further cementing its place as a crucial component for industry professionals. The J55 coupling's reputation is built on a foundation of technical credibility, backed by extensive research and applied expertise. Professional engineers often regard its implementation as a best-practice standard, illustrating its authoritative role in oil and gas operations. Its design, developed through rigorous scientific validation and field testing, meets critical performance criteria essential for safe and efficient drilling. This reputation is solidified through third-party validations and certifications, which affirm its capacity to deliver excellence in the field. Considerations for selecting the J55 coupling involve analyzing operational contexts and environmental factors, where its specifications align closely with industry requirements. Evaluations based on these criteria affirm its position as a wise investment, offering high returns in terms of operational dependability and lifespan. Trust in this coupling is echoed throughout industry circles, where its consistent performance provides peace of mind for stakeholders. Supporting the prevention of potential hazards and ensuring continuity in operations, the J55 coupling emerges as a pivotal asset necessary for maintaining industrial integrity. Its role in facilitating performance and safety underlines its importance—a sentiment pervasive among those who prioritize reliability and efficiency in their day-to-day operations. As industry standards continue to evolve, the J55 coupling remains a steadfast choice, continually proving its worth in maintaining the delicate balance of safety and productivity in the energy sector.

Field experience showcases the J55 coupling’s practical application and efficiency in real-world scenarios. For example, operators have noted significant decreases in maintenance costs and incidents of equipment failure when employing this coupling. Real-world applications affirm its engineered qualities, demonstrating a proven record of reliable service throughout rigorous cycles. The coupling's durability, particularly in high-output environments, provides concrete evidence of its craftsmanship—further cementing its place as a crucial component for industry professionals. The J55 coupling's reputation is built on a foundation of technical credibility, backed by extensive research and applied expertise. Professional engineers often regard its implementation as a best-practice standard, illustrating its authoritative role in oil and gas operations. Its design, developed through rigorous scientific validation and field testing, meets critical performance criteria essential for safe and efficient drilling. This reputation is solidified through third-party validations and certifications, which affirm its capacity to deliver excellence in the field. Considerations for selecting the J55 coupling involve analyzing operational contexts and environmental factors, where its specifications align closely with industry requirements. Evaluations based on these criteria affirm its position as a wise investment, offering high returns in terms of operational dependability and lifespan. Trust in this coupling is echoed throughout industry circles, where its consistent performance provides peace of mind for stakeholders. Supporting the prevention of potential hazards and ensuring continuity in operations, the J55 coupling emerges as a pivotal asset necessary for maintaining industrial integrity. Its role in facilitating performance and safety underlines its importance—a sentiment pervasive among those who prioritize reliability and efficiency in their day-to-day operations. As industry standards continue to evolve, the J55 coupling remains a steadfast choice, continually proving its worth in maintaining the delicate balance of safety and productivity in the energy sector.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products