- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Role of Tubing Pup Joints in Oil and Gas Applications

Understanding Tubing Pup Joints An Essential Component in Oil and Gas Operations

In the oil and gas industry, the efficiency and reliability of drilling operations are of utmost importance. One often overlooked yet crucial component in this process is the tubing pup joint. This article aims to explore the significance, design features, and applications of tubing pup joints within the context of petroleum engineering.

What is a Tubing Pup Joint?

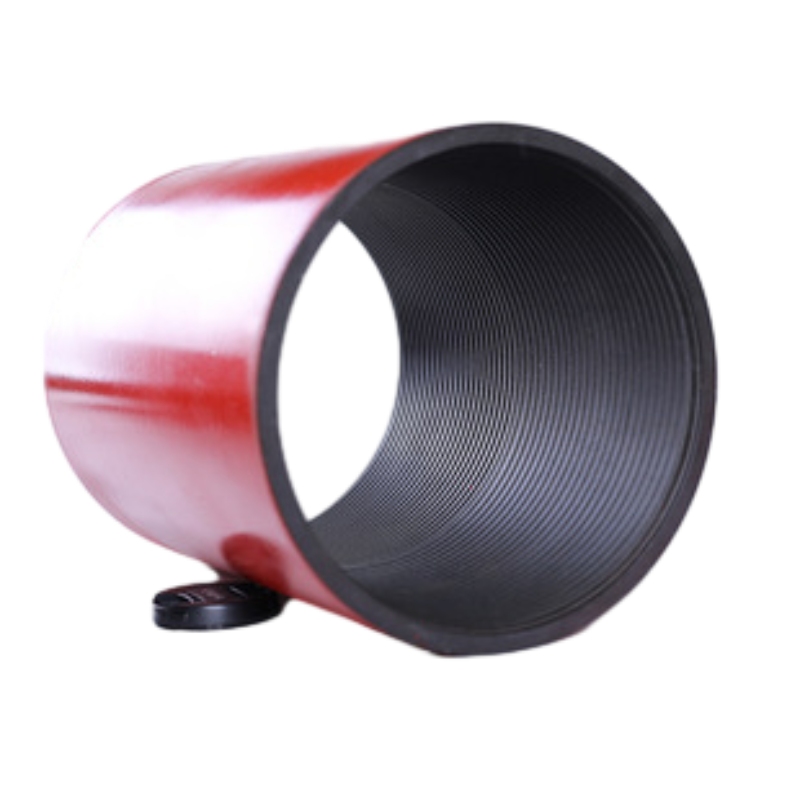

A tubing pup joint is a short section of pipe that is used in conjunction with the larger lengths of tubing that make up the wellbore

. Typically, these joints measure anywhere from a few inches to several feet in length, depending on the specific requirements of a drilling operation. Their primary purpose is to adjust the length of the tubing string, accommodate any changes in well depth, or facilitate the connection of other tubular components.Design Features

The design of tubing pup joints is critical to their functionality. They are usually made from high-quality steel, which offers high tensile strength, durability, and resistance to corrosion. The outer and inner surfaces are designed to minimize friction and wear, ensuring smooth operation as they undergo numerous pressure cycles during drilling and production.

Pup joints can come with various thread types and configurations, allowing them to be easily connected to other pipe sections. The common thread types include buttress, API, and premium threads, each offering different benefits in terms of sealing capabilities and resistance to mechanical failures. Additionally, pup joints may feature specialized coatings to enhance corrosion resistance, particularly in hostile environments like offshore drilling rigs.

Applications

tubing pup joint

Tubing pup joints serve multiple purposes throughout the lifecycle of a well

1. Length Adjustment In many drilling projects, the total length of tubing or piping required might not meet standard lengths. Tubing pup joints allow operators to custom-fit the tubing string to specific depths, thus ensuring operational efficiency.

2. Installation of Equipment Pup joints are often used to install various types of downhole equipment, such as pumps and sensors, that are critical for monitoring and extracting hydrocarbons. The flexibility provided by these joints allows for easier integration of additional tools.

3. Compensation for Wear Over time, tubing can wear down due to the extreme conditions it faces, including high pressures and corrosive substances. By utilizing pup joints, operators can replace damaged sections without needing to change the entire tubing string, which saves both time and costs.

4. Facilitating Completion and Workover Operations During completion or workover activities, it may be necessary to change the length of the tubing string quickly. Tubing pup joints allow for such adjustments with minimal downtime, contributing to a more efficient operation.

Conclusion

The tubing pup joint is a simple yet invaluable component in the arsenal of tools available to oil and gas operators. Its ability to provide flexibility in well construction, accommodate changes in equipment, and facilitate efficient repairs plays a crucial role in maintaining optimal production levels. As technology advances and drilling techniques evolve, the role of tubing pup joints may become even more significant, underscoring the need for continuous innovation and improvement in their design and application.

Whether in challenging offshore environments or straightforward onshore drilling sites, tubing pup joints represent the intricacies of engineering and the attention to detail that is vital for successful oil and gas operations. Knowing the role they play can help both industry professionals and stakeholders appreciate their contribution to the overall efficiency and safety of drilling endeavors.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025