- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Seamless Tubing Connection Solutions for Efficient Industrial Applications and Enhanced Performance

Seamless Tubing Couplings A Vital Component in Modern Engineering

In the realm of modern engineering, the significance of seamless tubing couplings cannot be overstated. These essential components play a crucial role in various industries, including oil and gas, chemical processing, and aerospace. Their design and functionality contribute significantly to the efficiency and safety of fluid and gas transport systems.

Seamless tubing itself is crafted from solid rounds of metal, which are heated and then pierced to create a hollow tube. This manufacturing process yields a product that is free of seams or welds, thereby eliminating potential weak points that can lead to failures under high pressure or extreme conditions. The seamless quality not only enhances the structural integrity of the tubing but also ensures a smoother flow of fluids, making it an ideal choice for critical applications.

Couplings are fittings that connect two lengths of tubing, allowing for a secure and reliable junction. In the context of seamless tubing, couplings are designed to maintain the same structural and mechanical properties as the tubing itself. This compatibility is crucial in ensuring that the entire system functions efficiently and safely. There are various types of couplings available, including threaded, flanged, and welded options, each offering distinct advantages based on the application.

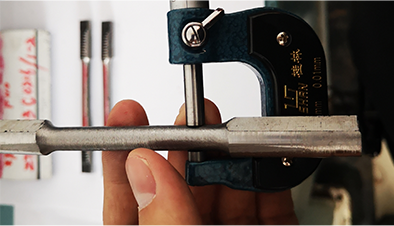

seamless tubing coupling

One of the key benefits of seamless tubing couplings is their ability to withstand high pressures and temperatures. This makes them particularly valuable in industries such as oil and gas, where pipelines are subjected to extreme operational stresses. The seamless design minimizes the risk of leaks, which can be catastrophic in such environments. Additionally, the absence of welds reduces the likelihood of corrosion or failure over time, resulting in lower maintenance costs and enhanced safety.

Moreover, the versatility of seamless tubing couplings extends to their material composition. They can be manufactured from various materials, including stainless steel, carbon steel, and exotic alloys, allowing for tailored solutions based on the specific requirements of an application. This adaptability is essential as industries continue to evolve and demand more from their materials.

In conclusion, seamless tubing couplings are a vital component in a wide array of engineering applications. Their seamless construction provides superior strength and reliability, while their ability to withstand harsh conditions makes them indispensable in critical industries. As technology advances and industries demand even more efficient and safe solutions, the role of seamless tubing couplings will only continue to grow. Engaging with reputable manufacturers who understand the importance of quality and precision in these components will be essential for ensuring the success of any engineering project.

-

Tubing coupling plays a significant role in the chemical industryNewsApr.03,2025

-

The Importance of Tubing Crossover in Various Industrial FieldsNewsApr.03,2025

-

The characteristics and important role of Tubing Pup JointNewsApr.03,2025

-

Characteristics and functions of Pup jointNewsApr.03,2025

-

Characteristics and Functions of Pup Joint PipeNewsApr.03,2025

-

Application of Coupling Casing in Various ScenariosNewsApr.03,2025