- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 05:57

Back to list

what is bull plug

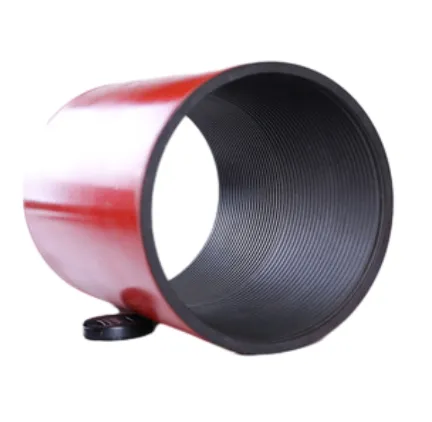

Understanding the Bull Plug A Comprehensive Guide for Oil and Gas Professionals

Experience plays a critical role in the effective use of bull plugs. Operators and engineers with hands-on experience can swiftly determine the correct type and material of the bull plug needed for a specific task. This level of expertise ensures that operations continue without a hitch, and the risk of equipment failure is minimized. Furthermore, the authoritative knowledge possessed by industry veterans is invaluable. These experts often provide training and guidelines for younger professionals on the proper installation and maintenance of bull plugs. This transfer of knowledge helps maintain high safety standards and operational efficiency across the board. Trustworthiness is another paramount factor when considering bull plugs. The reliability of these components is non-negotiable, given their role in maintaining the safety of high-pressure environments. Manufacturers that are committed to quality assurance and rigorous testing typically provide the most dependable products. Professionals in the industry often look for certifications and compliance with international standards as a testament to a bull plug’s reliability and performance. One must also appreciate the technological advancements in the design and manufacturing of bull plugs. Continuous research and development efforts have led to improvements in the materials used, providing better resistance to corrosion and pressure. Some modern bull plugs come with advanced sealing technologies that offer better durability and longevity, thus providing more reliable solutions in challenging drilling and pipeline operations. In conclusion, the humble bull plug is more than just a simple fitting in the realm of oil and gas. It embodies the blend of technical expertise, hands-on experience, authoritative knowledge, and trustworthiness. Understanding its role and application can significantly enhance operational safety and efficiency, making it an indispensable tool in any oil and gas professional's toolkit. Assessing the quality, design, and appropriate application of bull plugs can lead to more efficient and safe drilling operations, highlighting their critical role in the complex processes of the oil and gas industry.

Experience plays a critical role in the effective use of bull plugs. Operators and engineers with hands-on experience can swiftly determine the correct type and material of the bull plug needed for a specific task. This level of expertise ensures that operations continue without a hitch, and the risk of equipment failure is minimized. Furthermore, the authoritative knowledge possessed by industry veterans is invaluable. These experts often provide training and guidelines for younger professionals on the proper installation and maintenance of bull plugs. This transfer of knowledge helps maintain high safety standards and operational efficiency across the board. Trustworthiness is another paramount factor when considering bull plugs. The reliability of these components is non-negotiable, given their role in maintaining the safety of high-pressure environments. Manufacturers that are committed to quality assurance and rigorous testing typically provide the most dependable products. Professionals in the industry often look for certifications and compliance with international standards as a testament to a bull plug’s reliability and performance. One must also appreciate the technological advancements in the design and manufacturing of bull plugs. Continuous research and development efforts have led to improvements in the materials used, providing better resistance to corrosion and pressure. Some modern bull plugs come with advanced sealing technologies that offer better durability and longevity, thus providing more reliable solutions in challenging drilling and pipeline operations. In conclusion, the humble bull plug is more than just a simple fitting in the realm of oil and gas. It embodies the blend of technical expertise, hands-on experience, authoritative knowledge, and trustworthiness. Understanding its role and application can significantly enhance operational safety and efficiency, making it an indispensable tool in any oil and gas professional's toolkit. Assessing the quality, design, and appropriate application of bull plugs can lead to more efficient and safe drilling operations, highlighting their critical role in the complex processes of the oil and gas industry.

Next:

Latest news

-

Understanding Tubing Crossover: Tools for Enhanced Oilfield OperationsNewsAug.08,2025

-

Tubing Pup Joint: The Ideal Choice for Oil and Gas OperationsNewsAug.08,2025

-

Tubing and Casing: Essential Components in Oil and Gas ProductionNewsAug.08,2025

-

Introduction to Tubing CouplingNewsAug.08,2025

-

Casing Pup Joint: The Essential Component for Oil and Gas OperationsNewsAug.08,2025

-

Casing Coupling: The Essential Link in Well ConstructionNewsAug.08,2025

Related Products