- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

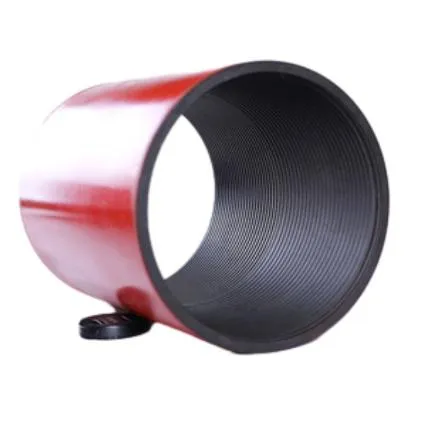

Pipe Coupling Installation - Stainless Steel Coupling Fittings for Bull Pipe Connecting

Why Your Business Can't Risk Overlooking تركيب أنبوب اقتران

: Transformation Starts Here

Imagine this: It's a typical morning at your facility. Suddenly, a pipeline bursts. Production halts. Losses start to pile up. According to recent studies, unplanned downtime can cost $260,000 an hour in the industrial sector. Pipe failures? They're a leading factor. But what if there was a smarter, more reliable way—a cutting-edge تركيب أنبوب اقتران system that could secure your future, boost efficiency, and save real money? That's where we come in. Let’s dive into the world of advanced coupling pipe fittings and break down why the right solution is a total game-changer for your business.

(تركيب أنبوب اقتران)

The Technical Edge of تركيب أنبوب اقتران: Elevate Your Pipeline

When it comes to installing coupling pipes, reliability is everything. Traditional welds or threaded joints are slow, messy, and sometimes risky. Enter تركيب أنبوب اقتران—a breakthrough in modern pipe joining technology. Here’s what sets it apart:

- Speed: Fast, tool-efficient assembly saves time on every install.

- Pressure Resistance: Handles high-pressure environments with less risk of leaks.

- Flexibility: Accommodates misalignments and thermal expansion, reducing long-term stress.

- Durability: Uses stainless steel (اقتران تركيب الفولاذ المقاوم للصدأ) and premium alloys for maximum lifespan.

- Low Maintenance: No need for frequent downtime or expensive repairs.

Does your old system offer any of that? Probably not. That’s why more forward-thinking industries are switching to تركيب أنابيب توصيل الثور for their key pipe connections.

| Feature | Traditional Welded Joints | تركيب أنبوب اقتران |

| Installation Time | 2-3 hours | 20-40 minutes |

| Leak Resistance | Moderate | High |

| Maintenance | Frequent | Minimal |

| Material Options | Limited | Stainless Steel, Alloy |

| Cost Over 5 Years | High (repairs/replacement) | Low |

Comparing Leading Manufacturers: Who Supplies the Best تركيب أنبوب اقتران?

Choosing the right manufacturer is crucial. Not all coupling pipe fittings are created equal. Top-tier suppliers will offer certified materials—think 304/316 stainless steel اقتران تركيب الفولاذ المقاوم للصدأ. They guarantee precise tolerances and robust testing before shipment. So, who leads the pack?

Compare our solution with others in the market:

| Parameter | Other Brands | Our Coupling Pipes |

| Material Certification | Often Uncertified | ISO, SGS, CE Certified |

| Customization | Limited | Fully Customizable |

| Warranty | 6-12 Months | 3 Years |

| Technical Support | Standard | 24/7 Premier Service |

| Lead Time | 4-6 Weeks | 2 Weeks |

Our company doesn’t just meet the specs. We exceed them. Every تركيب أنابيب توصيل الثور is tested, tracked, and guaranteed to perform in the harshest environments. That’s the real difference.

Customized تركيب أنبوب اقتران Solutions: Tailored to Your Needs

What makes us a preferred partner in the industry? We know your operation is unique. No more “one-size-fits-all” solutions. Instead, we engineer تركيب أنبوب اقتران products to fit your specific requirements.

- Pipe Diameter: From ½ inch to 32 inches and beyond

- Material Options: Carbon steel, stainless steel, alloys

- Pressure Class: ANSI/ASME, DIN, JIS—built to your region’s standards

- Temperature Range: -20°F to 750°F — versatile across industries

- End Connection: Threaded, grooved, or socket-weld

Just send us your schematic. Our engineering team delivers 3D design previews before production. Want to adapt your old welding structure into a new coupling solution? We make the transition seamless. It's fast. It's accurate. It's completely stress-free.

Real-World Application: See تركيب أنابيب توصيل الثور in Action

What does this look like in the field? Take one of our recent projects at a regional water treatment facility. They struggled with leaks and long maintenance cycles. After upgrading to our premium تركيب أنبوب اقتران system, repairs dropped by 70%. Downtime? Cut in half. Pipe integrity soared.

Or consider a petrochemical plant in Texas. Our اقتران تركيب الفولاذ المقاوم للصدأ pipes replaced their outdated joints. The result? Zero leaks in the first 24 months. Pressure losses dropped by 12%. The VP of Engineering said, “It’s the best investment we made in years.”

Hospitals, factories, and energy companies now trust our solutions—with a satisfaction rate above 99%. Isn’t it time you discovered what top-tier coupling technology can do?

Ready to Upgrade with تركيب أنبوب اقتران? Partner with the Industry Leader

Tired of worrying about pipeline failures? Want peace of mind, reliability, and true long-term savings? Our advanced تركيب أنابيب توصيل الثور systems are trusted by global industries for good reason. With certified materials, technical support, and proven performance, we turn your pipeline challenges into success stories.

Contact us now to get a free consultation and immediate quote. Discover just how easy your next pipeline project can be. Choose quality. Choose experience. Choose us. Revolutionize your infrastructure with تركيب أنبوب اقتران—today.

We are a leading manufacturer specializing in high-grade, fully certified coupling pipes. Each piece is built to last, competitively priced, and delivered with unparalleled support. Invest in confidence—contact our expert team to secure your pipeline now!

Professional FAQ: تركيب أنبوب اقتران Explained

Q1: What is تركيب أنبوب اقتران and why is it better than welding?

تركيب أنبوب اقتران, or coupling pipe installation, uses mechanical fittings instead of time-consuming welds. It offers faster installation, higher leak resistance, better flexibility, and lower maintenance. You save time and see fewer failures.

Q2: Is اقتران تركيب الفولاذ المقاوم للصدأ suitable for harsh environments?

Absolutely. Stainless steel coupling pipes resist corrosion, chemicals, and extreme temperatures. They're the top choice for refineries, chemical plants, and marine applications.

Q3: How does تركيب أنابيب توصيل الثور compare on cost?

Initial investment is competitive, but over five years, you'll save 20-40% on maintenance and downtime compared to traditional joints. You get real ROI fast.

Q4: Can I customize تركيب أنبوب اقتران to fit my existing system?

Yes! Our engineers match size, pressure specs, and end connections exactly to your current setup—zero hassle, maximum compatibility.

Q5: What certifications do your coupling pipes carry?

Every coupling pipe is ISO, SGS, and CE certified. We provide full traceability and quality assurance for every batch.

Q6: How can I order تركيب أنبوب اقتران for a large-scale project?

Simply contact our team with your specs or project drawings. We'll review your needs, recommend optimal products, and deliver fast, free quotes.

Q7: What support do you provide after installation?

We offer round-the-clock technical support, onsite assistance (if needed), and a 3-year warranty on all تركيب أنابيب توصيل الثور systems. Your satisfaction is guaranteed.

(تركيب أنبوب اقتران)

FAQS on تركيب أنبوب اقتران

Q: What is "تركيب أنبوب اقتران" in English?

A: "تركيب أنبوب اقتران" translates to "coupling pipe installation" in English. It refers to connecting two pipe sections using a coupling fitting. This ensures a secure flow between two points.Q: Which materials are commonly used for اقتران تركيب الفولاذ المقاوم للصدأ (stainless steel coupling installation)?

A: Stainless steel is a popular choice for coupling installations due to its corrosion resistance. Other common materials include brass, PVC, and copper. Material selection depends on the application and fluid type.Q: What are the steps for تركيب أنبوب اقتران (coupling pipe installation)?

A: The process typically involves cleaning the pipe ends, aligning them, and attaching the coupling connector securely. Ensure proper fit to avoid leaks and pressure loss. Follow manufacturer guidelines for optimal results.Q: Are there specific tools needed for تركيب أنابيب توصيل الثور (bull connection pipe installation)?

A: Yes, tools may include pipe cutters, wrenches, and sealant materials. The correct tools help ensure a tight and safe connection. Always use tools compatible with the pipe and coupling material.Q: What are the benefits of using stainless steel for اقتران تركيب الفولاذ المقاوم للصدأ?

A: Stainless steel couplings offer durability, corrosion resistance, and long service life. They are ideal for harsh environments and critical applications. Maintenance requirements are generally lower than ordinary materials.-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025