- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Functionality and Importance of Vacuum Hose Coupling in Automotive Systems

Understanding Vacuum Hose Couplings A Key Component in Fluid Systems

Vacuum hose couplings are essential components in various industrial applications, particularly in systems that involve the transfer of fluids and gases. These couplings are designed to connect hoses securely to other equipment, allowing for the efficient movement of air, fluids, or vacuum pressures. Understanding the function, types, and significance of vacuum hose couplings is vital for anyone involved in manufacturing, automotive, or even household applications where fluid systems are utilized.

Function of Vacuum Hose Couplings

At its core, the primary function of a vacuum hose coupling is to create a reliable connection that prevents leaks while withstanding the pressure dynamics within the system. In many cases, these couplings are used in environments where a vacuum must be maintained to ensure system efficiency. For example, vacuum systems used in packaging industries require perfect sealing to avoid contamination and maintain product integrity.

Moreover, these couplings facilitate the movement of fluids in automotive systems, such as in intake manifolds for engine performance or in brake systems where vacuum is crucial for operation. Any failure in the coupling can lead to system inefficiencies, potentially causing damage to the equipment or even safety hazards.

Types of Vacuum Hose Couplings

Vacuum hose couplings come in various types, each designed for specific applications and requirements. Some of the most common include

1. Barbed Couplings These are widely used for low-pressure applications. They feature pronounced barbs that grip the inner walls of the hose, ensuring a secure connection. Barbed couplings are ideal for environments where quick disassembly and reassembly are advantageous.

2. Flanged Couplings Usually employed in industrial settings, these couplings offer a flat surface for easy attachment. Flanged couplings are bolted together to provide a robust and stable connection, suitable for high-pressure situations.

vacuum hose coupling

3. Cam Lock Couplings Known for their easy connection and disconnection, cam lock couplings are often used in situations where hoses need to be frequently changed. The design allows for quick and efficient operations, making them popular in agricultural, chemical, and food processing industries.

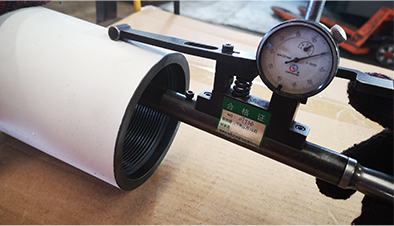

4. Threaded Couplings These couplings are secured with threads, which can provide a very tight and leak-proof connection. They are commonly found in professional fluid handling applications.

5. Quick Disconnect Couplings These are designed for rapid connection and disconnection, which is critical in applications where hoses need to be regularly changed without any tools.

Importance of Proper Coupling Selection

Choosing the right vacuum hose coupling is crucial for the integrity of the system. Factors such as the type of fluid being transferred, temperature, pressure requirements, and hose material must all be taken into account. An improperly selected coupling can lead to leaks, which not only affect system performance but can also pose safety risks.

Using the correct coupling can also enhance the lifespan of the hose and the connected equipment. Regular inspections and maintenance of the couplings are necessary to ensure they remain in good condition and to prevent potential failures.

Conclusion

Vacuum hose couplings play a critical role in ensuring the efficiency and safety of fluid systems across various industries. Their ability to create secure and leak-proof connections allows for the effective management of air, liquids, and gases. By understanding the different types of couplings available and their specific applications, individuals and businesses can make informed decisions that enhance their operational efficiency and safety. Proper selection and maintenance of vacuum hose couplings not only promote system reliability but also contribute to the longevity of the equipment involved.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025